מכונת אריזה מקפאת

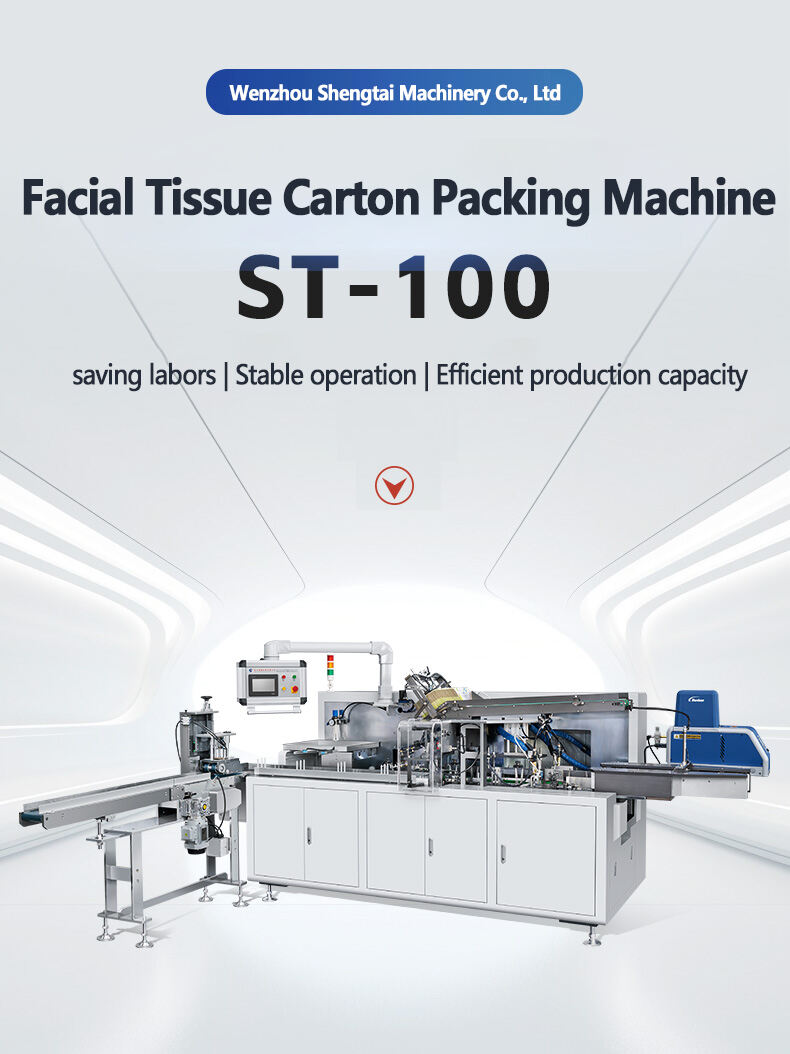

מכונת אריזה לקרטונים היא חומרה אוטומטית מתוחכמת שפותחה כדי לארוז מוצרים באופן יעיל לתוך קריטים או תיבות. מכונה רב-תכליתית זו מאיצה את תהליך האריזה על ידי ביצוע מספר פעולות, לרבות הקמת קריט, טעינת מוצר וסגירה, כולן בתנועה רציפה אחת. המכונה עושה שימוש בטכנולוגיית מנוע סרוו מתקדמת ובמערכות שליטה מדויקות כדי להבטיח פעולות אריזה מדויקות ועקביות. היא יכולה להתמודד עם גודלי קרטון ואופייני סגנונות שונים, ולכן היא מתאימה לתעשייה מגוונת, הכוללת תרופות, מזון ושתייה, קוסמטיקה וטובין צרכניים. עיצוב המודולרי של המכונה מאפשר התאמה והטמעה קלה בשרשראות הייצור הקיימות, בעוד הבנייה החזקה שלה מבטיחה ביצועים אמינים בסביבות תעשייה קשות. מכונות קרטון מודרניות מצוידות בממשק משתמש קל לשימוש, אשר מאפשר שינוי פורמט מהיר ו התאמות תפעוליות. הן כוללות גם תכונות ביטחון כמו מערכות עצירה דחופה ומחיצות הגנה כדי להבטיח את ביטחון המפעיל. המכונות מסוגלות להגיע למהירות של עד 120 קרטונים לדקה, תלוי במודל ויישום. מודלים מתקדמים כוללים תכונות של בקרת איכות, כגון אימות ברקוד, זיהוי כשלון במוצר ומערכות דחייה אוטומטיות למאריזות פגומות.