औद्योगिक कागज कटर मशीन

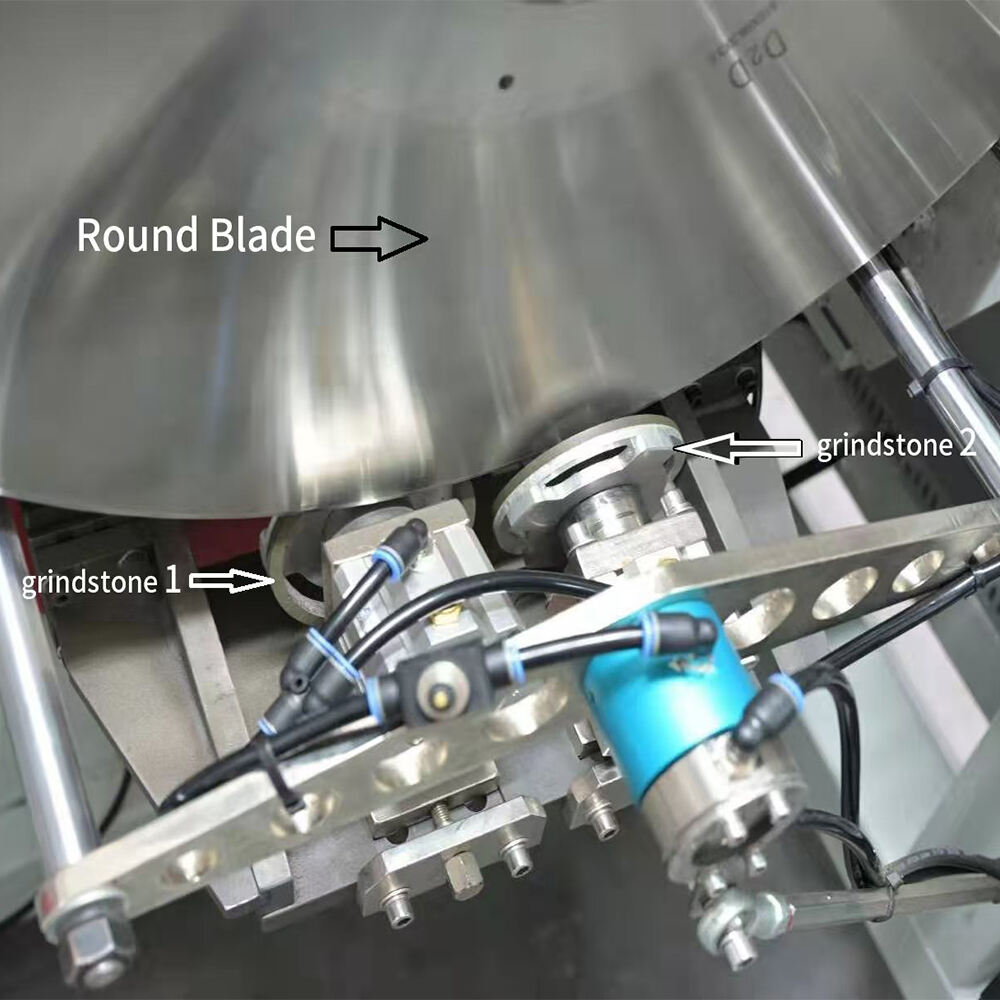

औद्योगिक पेपर कटर मशीन आधुनिक मुद्रण और विनिर्माण संचालन का एक महत्वपूर्ण हिस्सा है, विभिन्न प्रकार के पेपर सामग्री के लिए सटीक और कुशल काटने के समाधान प्रदान करती है। यह उन्नत उपकरण मजबूत यांत्रिक इंजीनियरिंग के साथ-साथ उन्नत डिजिटल नियंत्रणों को जोड़ती है ताकि पेपर, गत्ता, और समान सामग्री की बड़ी मात्रा में सटीक काट प्रदान की जा सके। मशीन में आमतौर पर भारी ड्यूटी स्टील फ्रेम की बनी होती है, जिसमें एक हाइड्रोलिक काटने वाली प्रणाली होती है जो सख्त स्टील ब्लेड के माध्यम से काफी दबाव डाल सकती है। इसकी काटने की चौड़ाई 65 से 137 सेमी तक हो सकती है, जो विभिन्न उत्पादन आवश्यकताओं को पूरा करती है। प्रणाली में उन्नत सुरक्षा विशेषताएं शामिल हैं, जिनमें डुअल हैंड ऑपरेशन नियंत्रण, इन्फ्रारेड सुरक्षा पर्दे, और आपातकालीन बंद कार्यक्षमता शामिल हैं। आधुनिक औद्योगिक पेपर कटर में प्रोग्राम करने योग्य टच स्क्रीन इंटरफ़ेस लगे होते हैं जो ऑपरेटरों को काटने के क्रम को संग्रहीत करने और सटीकता के साथ 0.1 मिमी तक सेटिंग्स समायोजित करने की अनुमति देते हैं। मशीन की बहुमुखी प्रतिभा मानक पेपर से परे विभिन्न सामग्री को संभालने तक फैली हुई है, जिसमें सिंथेटिक पेपर, प्लास्टिक, और पतली धातु की चादरें शामिल हैं। प्रमुख तकनीकी विशेषताओं में स्वचालित ब्लेड अंतराल समायोजन, सामग्री संभालन के लिए हवा कुशन वाली मेज, और एकीकृत कचरा संग्रह प्रणाली शामिल हैं। ये मशीनें व्यावसायिक मुद्रण सुविधाओं, पैकेजिंग उद्योगों, और विशेष पेपर प्रसंस्करण संचालन में आवश्यक अनुप्रयोग पाती हैं, जहां वे बड़े उत्पादन रन में उत्पादकता में काफी सुधार करती हैं और स्थिर काटने की गुणवत्ता बनाए रखती हैं।