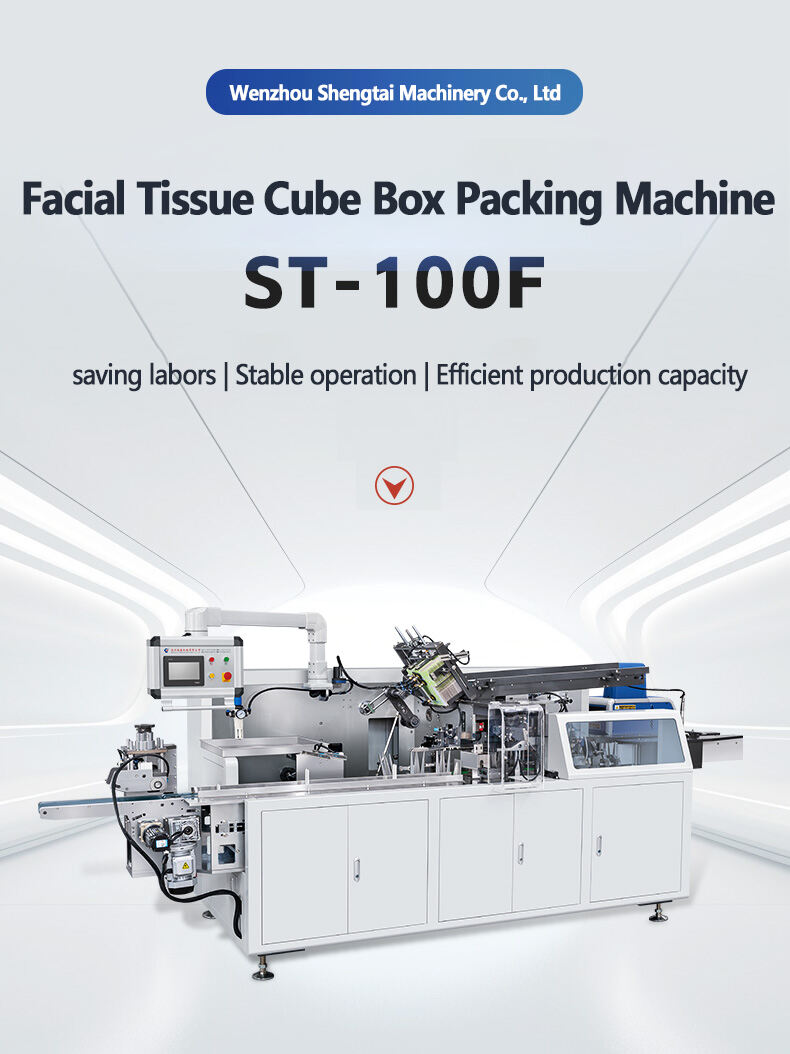

auto carton packing machine

The auto carton packing machine represents a breakthrough in packaging automation technology, designed to streamline and optimize the packaging process across various industries. This sophisticated equipment automatically forms, fills, and seals cartons with precision and efficiency, eliminating the need for manual intervention. The machine incorporates advanced sensors and control systems that ensure accurate product placement and consistent packaging quality. Its modular design allows for handling different carton sizes and configurations, making it highly versatile for diverse packaging needs. The system features an intelligent control interface that enables operators to easily adjust parameters and monitor performance in real time. With processing speeds capable of handling up to 20 cartons per minute, depending on the model and configuration, these machines significantly boost production efficiency. The integration of safety features, including emergency stop mechanisms and protective barriers, ensures operator safety while maintaining optimal performance. Additionally, the machine's compact footprint maximizes floor space utilization while providing easy access for maintenance and changeovers.