STZ-120 Strip pack coffee cartoning machine

Automatically, accurately and efficiently load food into the box,

Realize automatic production, improve production efficiency,

The whole machine shell is made of 304 stainless steel, food-grade material anti-pollution

- Overview

- Recommended Products

Product Description

STZ-120 is a fully automatic multifunctional cartoning machine: the shell of the whole machine is made of 304 stainless steel and 10MM thick transparent Plexiglass plate, and the appearance is simple and neat. This machine is suitable for a wide range of fields: such as daily necessities, cosmetics, food, medicine, hardware, health care products, etc. (please refer to the technical parameters of the equipment for specifications).

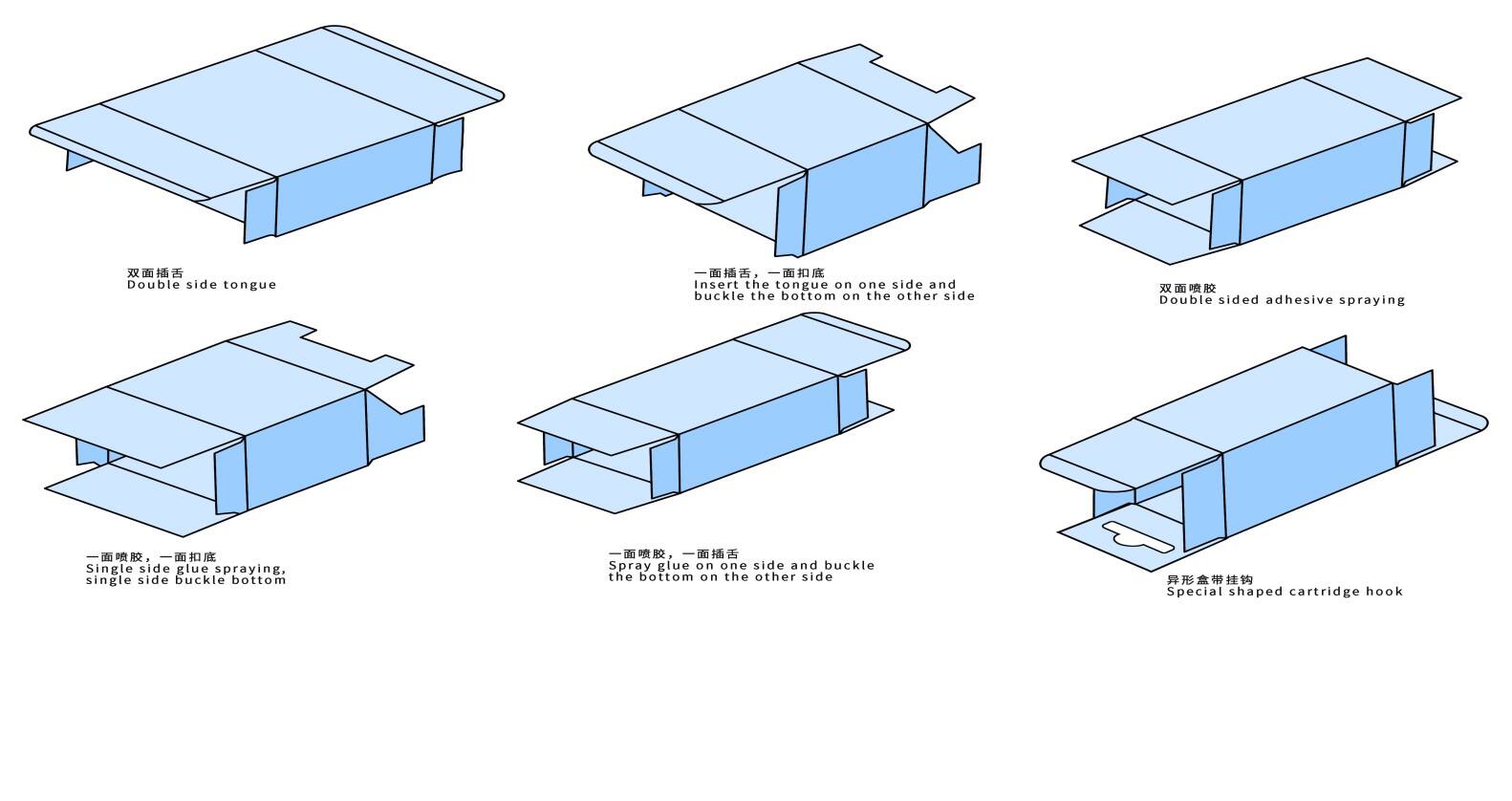

Suitable Carton Type:

Machine Performance and Parameters

| Model | STZ-120 |

| Carton material requirements | 280-350g/m²+(According the box size) |

| Packing specifications | L65-300mm×W35-140mm×H20-120mm |

| Packing speed | 30-80 box/min |

| Main motor power | 2kw |

| Power source | 2kw(deviation) |

| Power supply type | 380V 50HZ/60HZ 3 phase 5 wire |

| Machine noise | ≦80dB |

| Compressed air pressure | 0.5-0.8Mpa |

| Air consumption | 120-160L/min |

| Machine size | 4200mmx1430mmx1740mm |

| Machine weight | 2000kgs |

Packing Style and Specification

1、Flow Chart

2、Real Example

|

|

|

Main Features and Advantages

1. This machine adopts double suction box (upper and lower suction box) linkage structure, the size of the lower box is accurate and stable, which greatly reduces the failure rate of the lower box.

2. The machine adopts a single-axis transmission design, matching the cam divider and cam design, with high packing efficiency, stable operation and simple maintenance;

3. The station technology design of this machine is perfect; material transmission, box unloading, feeding, accurate box sealing, with detection,rejecting and other auxiliary stations ; when the equipment is running, the transmission of each component is light, stable, and low-noise, which greatly improves the equipment life cycle.

4. Adopt PLC and man-machine interface to automatically control the operating system, stepless frequency conversion speed regulation, high automated, intelligent modular integration of display screen, simple and easy operation (including Chinese and English versions).

5. This machine adopts China & world well-known brand electrical components, and the performance of the standard execution originals is stable and reliable. (Omron, Cisco, Schneider, AirTAC, etc...).

6. Safety measures: The main motor adopts the automatic shutdown alarm function of mechanical overload to ensure the safety of personnel using the machine.

7. Automatically reject packaged products that lack packaging or instructions to ensure the quality of packaged products.

8.It has the functions of fault display, alarm and finished product counting, etc., which is convenient for regular maintenance and troubleshooting.

9. In terms of the processing technology of mechanical parts, the materials used in this machine are strictly controlled, and the technical requirements of the parts are strictly followed;

10. Various automatic feeders and conveying mechanisms can be designed according to customer requirements.

11. Optional hot-melt glue machine can be equipped with hot-melt glue spraying glue sealing or hot-melt glue brushing device.

12. It can be used with aluminum-plastic packaging machine, pillow packaging machine, filling machine, soap machine, inkjet printer (or supervision code system), labeling machine, online weighing instrument, three-dimensional packaging machine, heat shrink packaging machine, Belt strapping machine, other production lines, etc. realize docking linkage production.

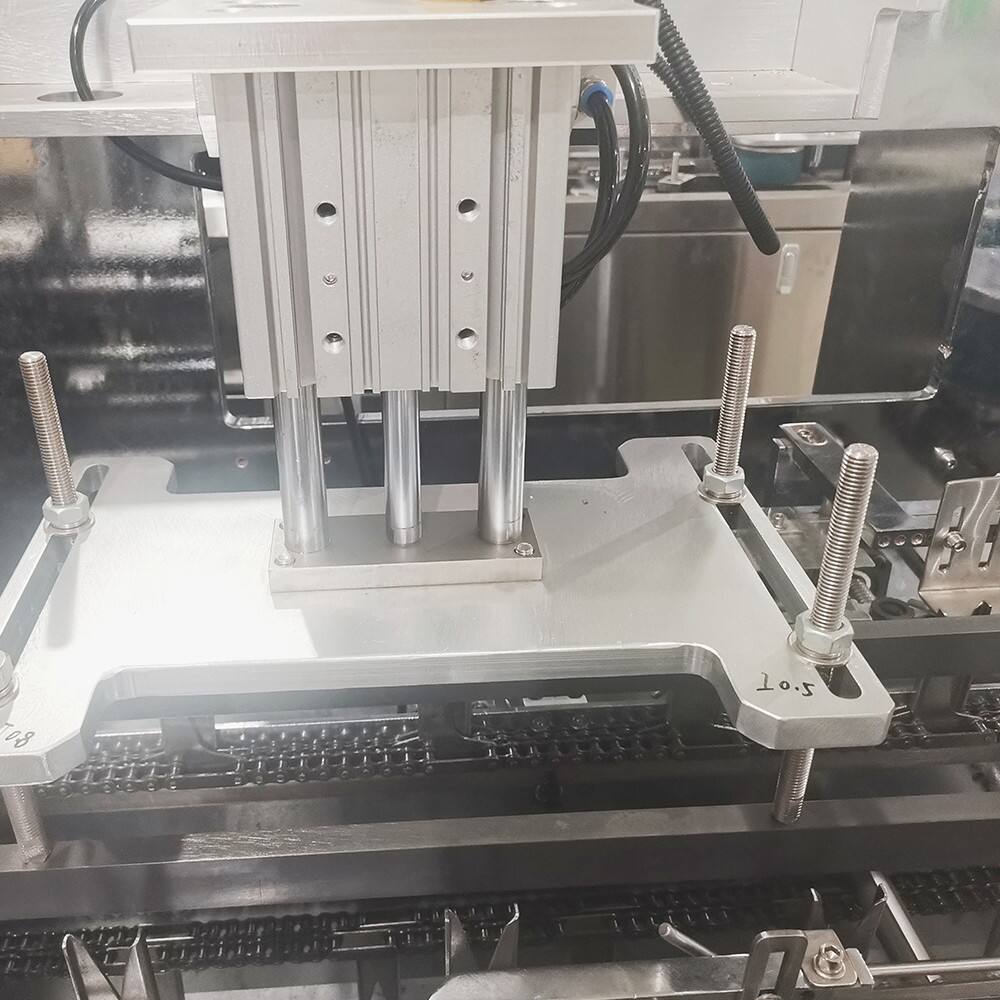

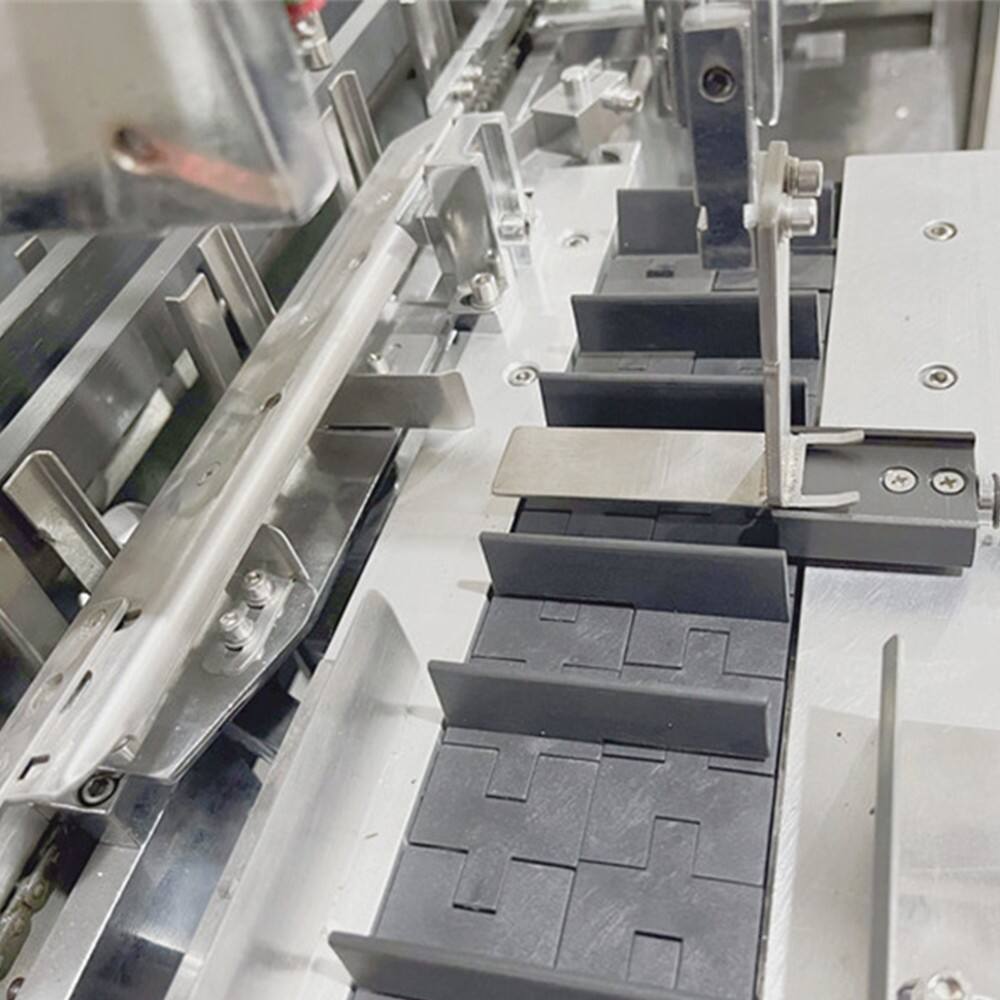

Equipment Details

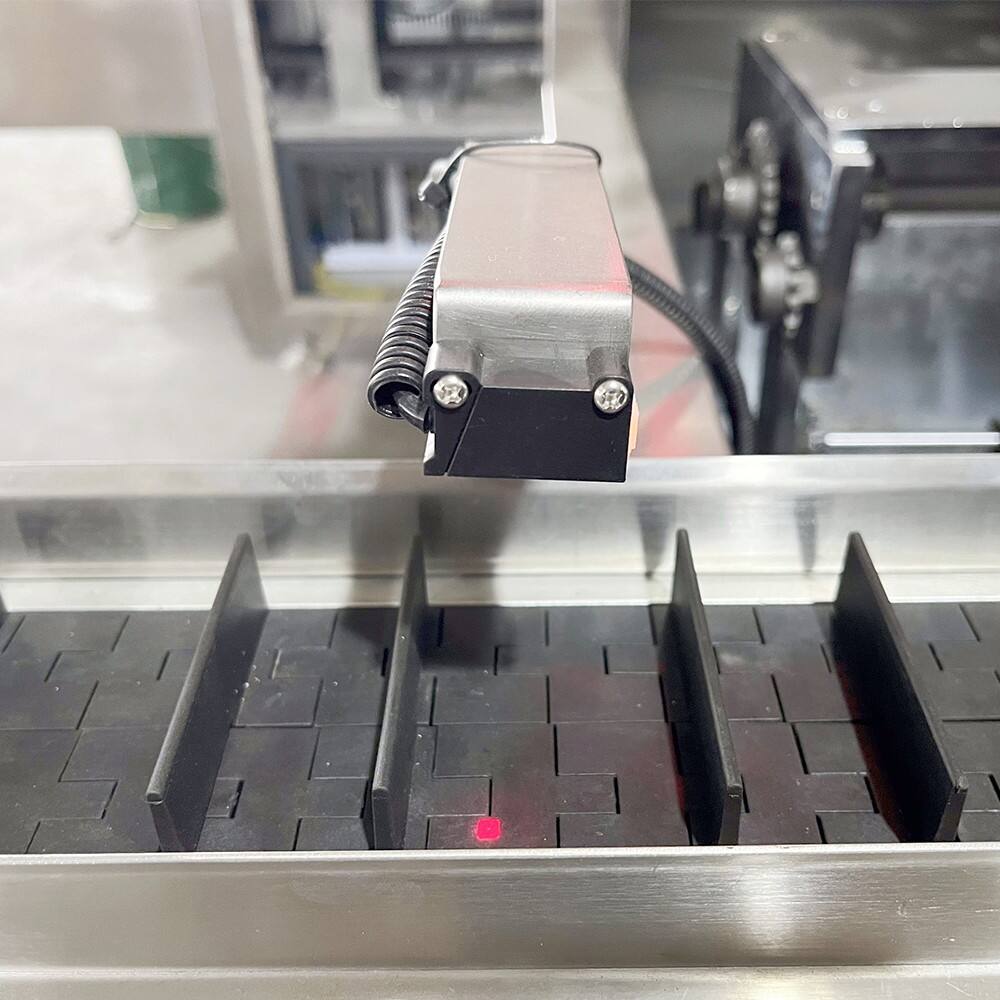

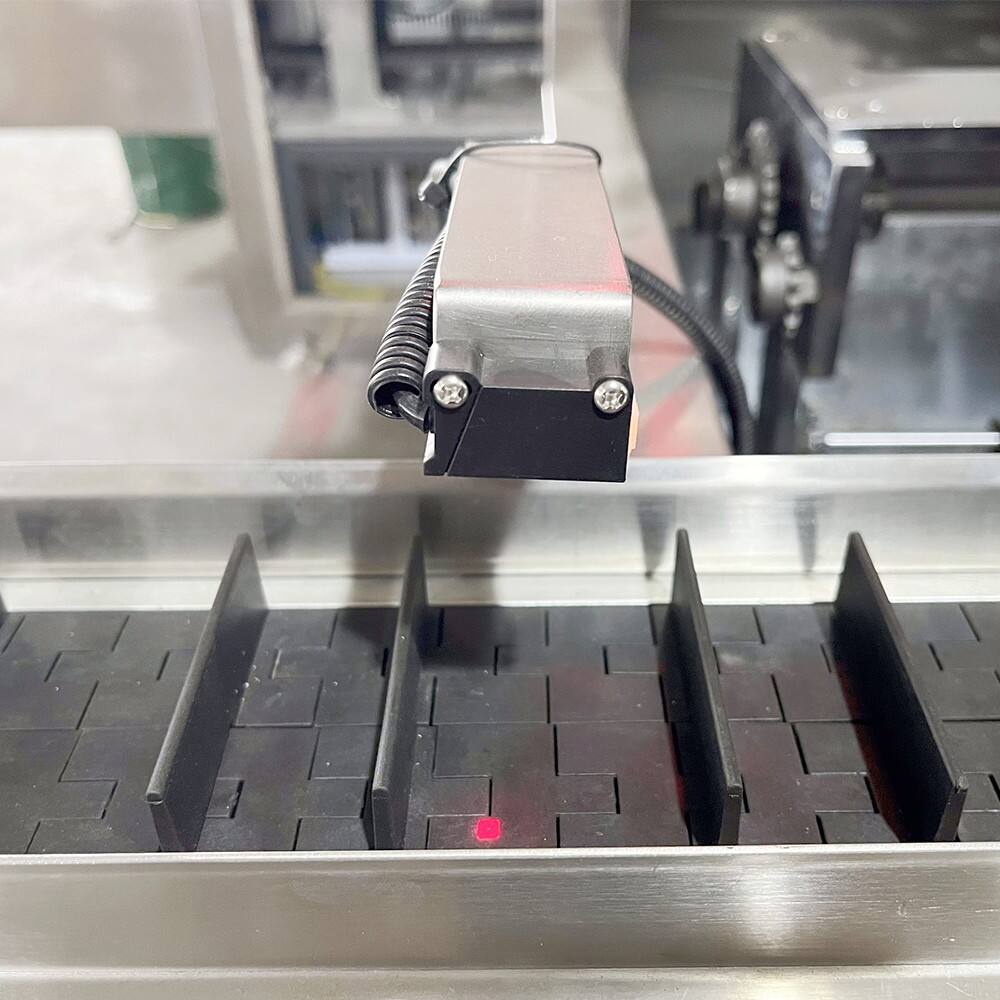

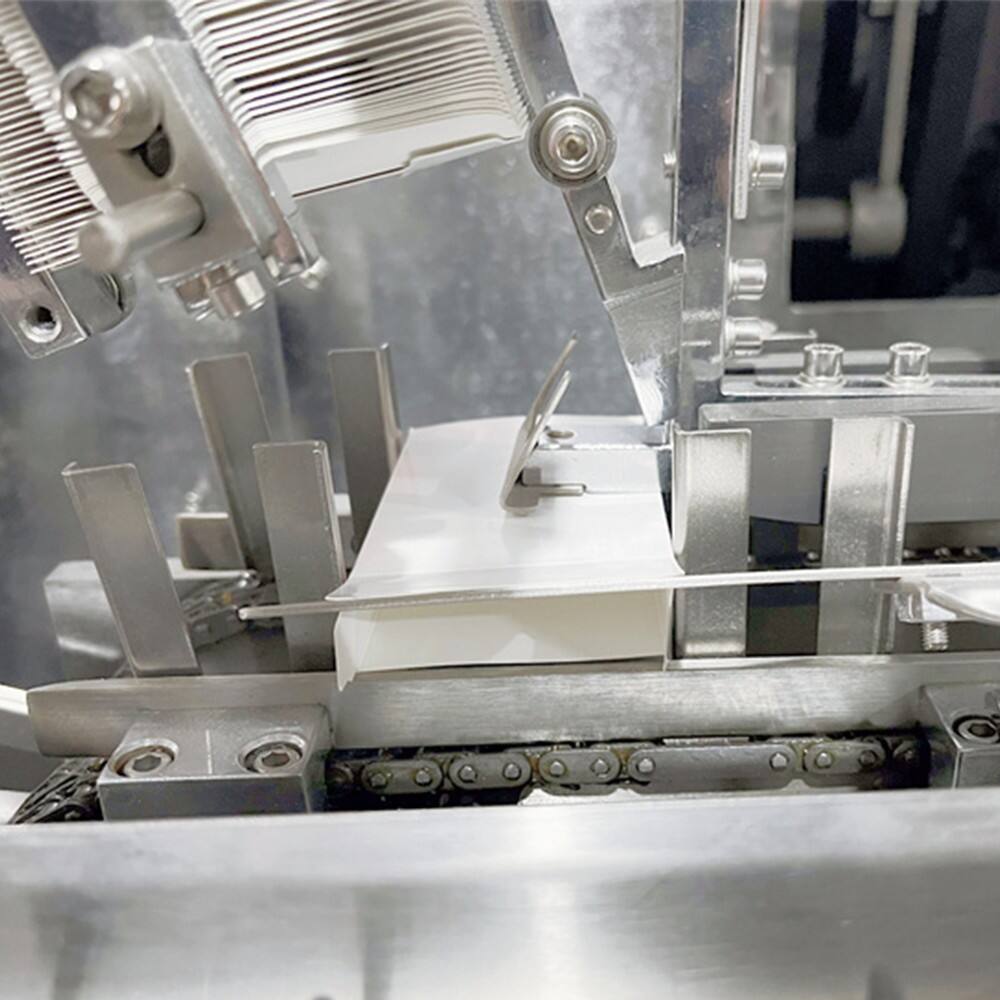

|

|

|

| Conveyor Belt - Adjustable length of the material bin according to the demand, with photoelectric detection function, in line with the industry requirements. | Upper and lower suction box-Automatically opens the box and waits for the material to enter | Upper pressing box cylinder - one button to lift up, easy to adjust the box specifications |

|

|

|

| Servo Pusher with Side Lug Opening-Automatically push the material into the box, The material into the box is not in place will be alarmed to deal with | Tongue insertion mechanism-automatic tongue insertion and sealing, also can be equipped with glue spraying and bottom buckling device. | Finished product output-Failed products are detected by photoelectricity and can be rejected here to guarantee 99.9% pass rate. |