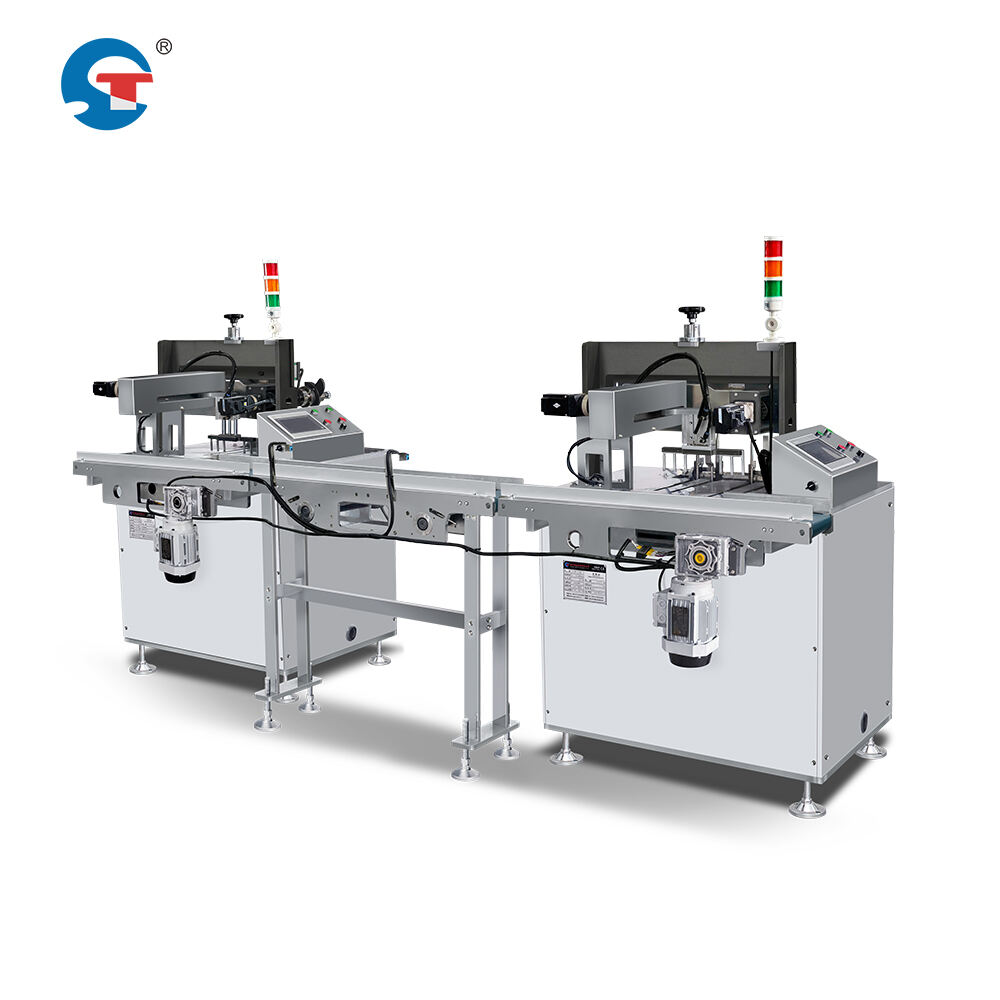

ST-Napkin Paper Auto Transfer Automatic Napkin Tissue Folding MachineWith Auto Transfer

Automatic paper sorting output for napkins.

High output, Servo paper separation, paper pushing,and automatic conveying,

Small body size saves space on the site

- Overview

- Recommended Products

Product Description

Automatic paper sorting output for napkins.

Four innovations of the machine

1、High output. The stable speed can reach 70 times/minute.

2、Complete functions.This machine is suitable for various specifications of tissues.

3、Rapid production. lt changing specifications is more convenient.

4、Convenient operation. Servo paper separation, paper pushing,and conveying, with a PLC control system that is easy to master.

Machine Performance and Parameters

| ltem/model | ST-Napkin PaperAuto Transfer |

| Paper towel specifications | 180mm-230mm |

| Packing speed | 70(times/minute) |

| Total power | 5.7kw |

| Power supply type | (3 phase 5 wire)380V 50Hz/60HZ |

| Machine noise | ≦80dB |

| Air supply | 0.5-0.8Mpa |

| Air comsumption | 120-160L/min |

| Outline dimensions | L1210mm×W940mm×H1375mm |

| Machine weight | 500kg |

Packing Style and Specification

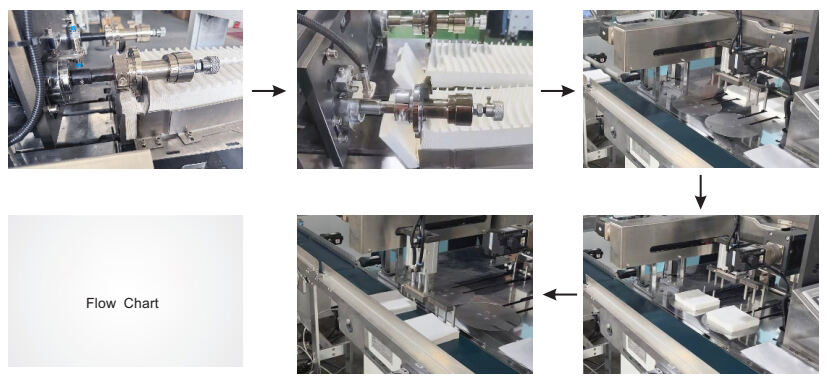

1、Flow Chart

Main Features and Advantages

1、According to the customer's requirements for the size and quantity of tissues.separate the tissues according to specifications, and carry out paper blocking and conveying to achieve the conversion of multiple specifications, More convenient adjustment

2、Change of specifications does not need change of molds, fast switching among various specifications and sizes can be realized.

3、Multiple options for paper output structure, unrestricted by site limitations.

4、Servo/step motor, touch screen, PLC control system and man-machine interface display make operation more clear and convenient. With high qutomation degree, the machine is more user-friendly.

Simple operation and adjustment, compact and reasonable structure, saving space on site.

6、The automatic material arranging and conveying mechanism is adopted to facilitate linked production with automatic production line, which can greatly reduce labor cst.

7、Adopting hollow ventilation hood design increases the lifespan of electrical appliances, prolongs the use of the machine, and has a more aesthetically pleasing appearance compared to old-fashioned machines.

8、Various conveying mechanisms and packaging machines can be designed according to the requirements of tissues.

Equipment Details

|

|

PLC display - adjustable speed, visualization of efficiency, precise indication of faults |

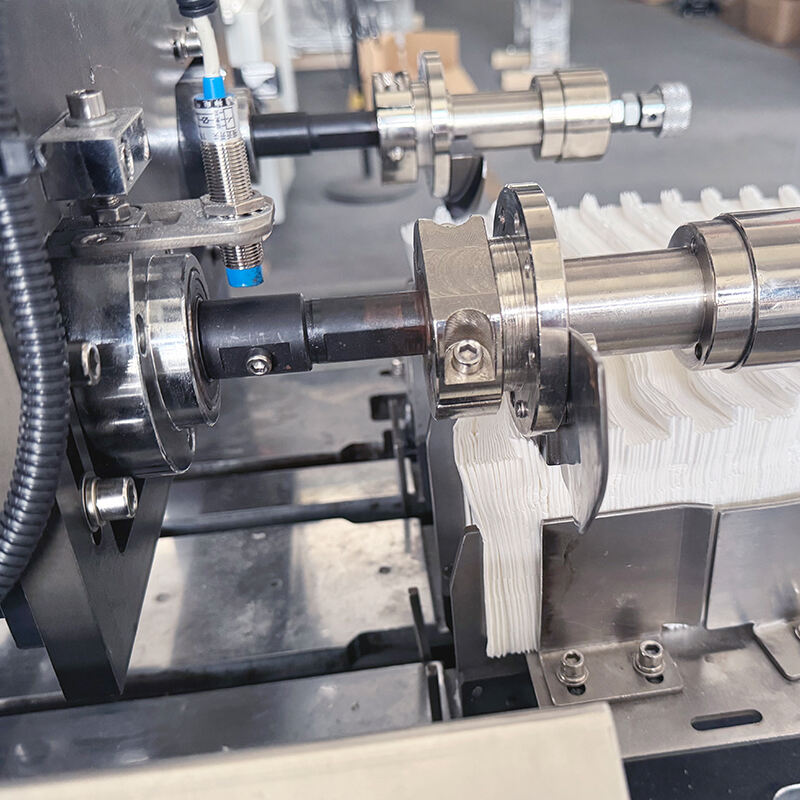

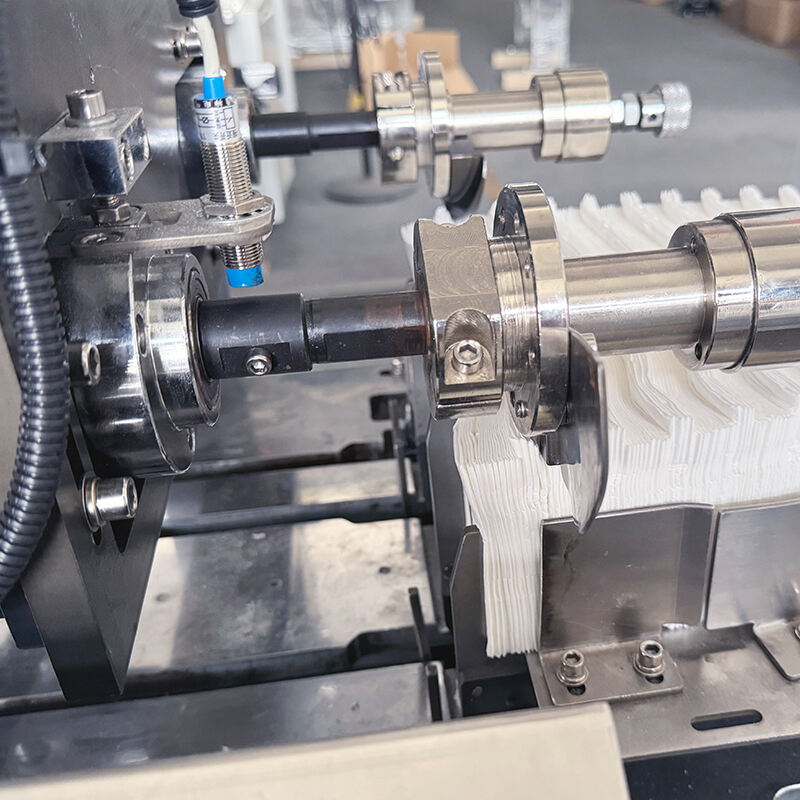

Servo paper separation-Separation of tissue paper according to set specifications |

|

|

Push paper for conveying-Automatically separates paper and pushes them onto conveyor belts |

Automatic material feeding conveyor-With material measurement photoelectricity, Automatic conveying according to settings |