ST-140B Automatic Paper Film Toilet Tissue Packaging Machine

6 patented technology,

Environmental protection paper film instead of plastic core innovation,

Speed up to 120 rolls / minute,

Flying film two-way fit gentle sealing, no material to save the film,

Belt expansion tolerance to protect the continuous operation of the production line

- Overview

- Recommended Products

- High capacity,stable speed of 120 packs/min.

- Quick change only 10-20 minutes.

- Fast operation, PLC control system to control.

Product Description

It is suitable for automatic paper wrapping of roll tissues.

Four innovations of the machine:

Machine Performance and Parameters

| Item/model | ST-140B |

| Paper quality | 0.03-0.05mm |

| Maximum roll size | Ф500mm |

| Maximum packing specification | L(90-130)mm,Ф95-130mm |

| Diameter of paper roll | 75-78mm |

| The weight of paper | 17-26g |

| Packing speed | 60-120 rolls/minute( stable 120) |

| Main Motor power | 1.5KW |

| Total power | 5.71KW |

| Power supply type | 3phase 4wire 380V 50Hz |

| Machine noise | ≤80dB |

| Air supply | 0.5-0.8 Mpa |

| Air consumption | 120-160L/min |

| Machine Size | 2966*2444*1723mm |

| Machine weight | 3500KG |

Packing Style and Specification

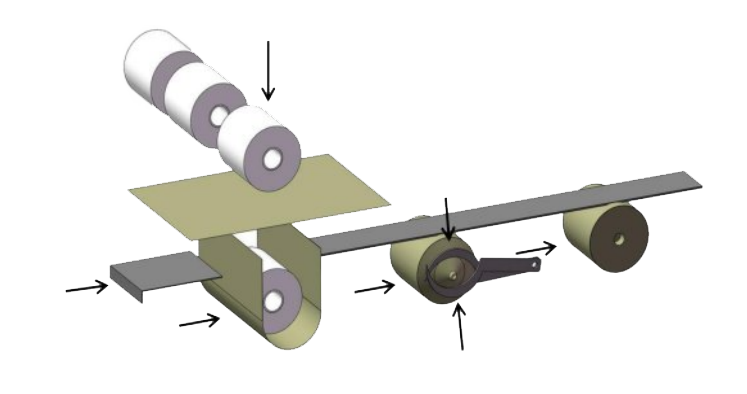

1、Flow Chart

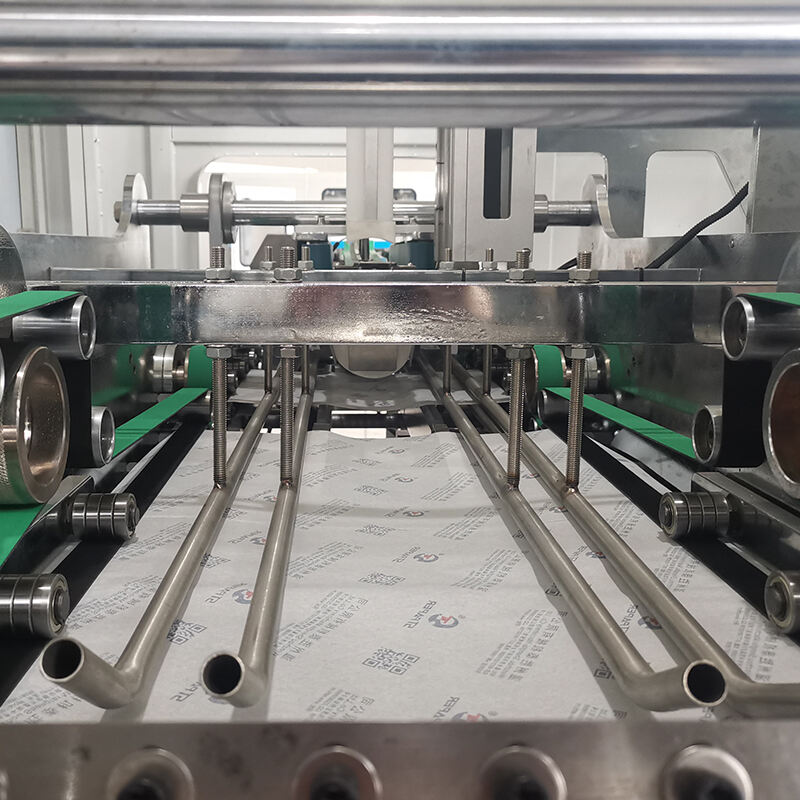

2、Real Example

|

|

|

Main Features and Advantages

1、The packaging forms of automatic feeding, paper cutting, paper suction, paper clamping and paper pressing are adopted. The structure is compact and reasonable, and the operation adjustment is simple.

2、Servo motor and touch screen, PLC programmable control system, HMI interface display operation is more clear and simple, high degree of automation, more humane.

3、Adjustment is convenient, all sizes can be quickly converted.

4、Changing the specifications does not require a large number of replacement molds, just adjust or replace individual components can be achieved.

5、The overload protection device of the main drive motor is adopted, which is safe and reliable.

Equipment Details

|

||

| Automatic material feeding conveyor-With material measurement photoelectricity, there are materials will be opened and boxed to ensure that 100% no empty packages | Film rolling mechanism-Multi-layer spools stretch the rolled film so that the rolled film will not be broken | Paper film separation、flying film mechanism-Photoelectric detection device according to the film tracking light spot position conveying servo transmission to the film wrapping and cutting device for film slitting |

| Grab film sealing mechanism-Gathering the left and right wrapping film by robot, gripping the film gently without breakage. | Finished product output-Failed products are detected by photoelectricity and can be rejected here to guarantee 99.9% pass rate. |