ST-550 Automatic Box Facial Tissue Shrink Wrapping Machine

Widely used in mass production packaging flow operation with high working efficiency. Including pharmaceutical, electronics, daily chemicals, cosmetics, auto parts, hardware, food and other industries.

Automatic film feeding and punching device and manually adjustable film guiding system as well as manually adjustable feeding and conveying platform, suitable for products of different widths and heights.

- Overview

- Recommended Products

Product Description

It is suitable for box products、daily goods wrapping.

Machine Performance and Parameters

| Item/model | ST-550 |

| Sealing and cutting form | Side seal type |

| sealing and cutting machine | |

| Power Supply | 380V/50-60HZ/3Phase |

| Packaging speed | According to product length |

| Packing height | 200mm |

| Packing width | 430mm |

| Package size | (W+H)≤550mm |

| Applicable film | (POF Half folded membrane) |

| Maximum film size | 700x280mm(Width X Outer Diameter) |

| Total power | 2.5kw |

| Platform height | 780-850mm |

| pressure | 0.5MPA (5 BAR) |

| Main material | Carbon steel |

| Overall size | 2610×1450×1530mm |

| Heat Shrink Machine | |

| Power Supply | 380V/50-60HZ/3Phase |

| Furnace body size | 1200x400x200mm |

| Conveying speed | 40m/min |

| Conveyor belt | Chain conveyor belt, roller sleeve, silicone hose |

| Total power | 12kw |

| Platform height | 780-850mm |

Real Example

|

|

Main Features and Advantages

1、The horizontal knife of the sealing part adopts vertical drive, the vertical knife adopts constant temperature side sealing knife, and the sealing line is straight and firm,Achieve beautiful sealing effect;

2、The constant temperature heating sealing and cutting system can be used to seal and cut POF and other industrial standard shrink films.Products with different packaging specifications and sizes can be completed only by hand wheel adjustment,which increases reliability and easier operation;

3、The longitudinal sealing knife can seal and cut continuously, and the product length is not limited;

4、Feeding length control: through the combination of electric eye detection and timer the length of adhesive film can be accurately controlled to make the shrinkage effect easier to control:

5、Automatic waste coiling is controlled by a separate motor, which will not crack due to too loose or too tight,and the waste is easy to disassemble;

6、The automatic blowing function can be added according to the needs of customers;

7、Front end power feed line and rear end non power storage platform can be selected as required.

Equipment Details

|

|

|

Conveyor belt - with photoelectric detection to control the number of wrapped cassettes |

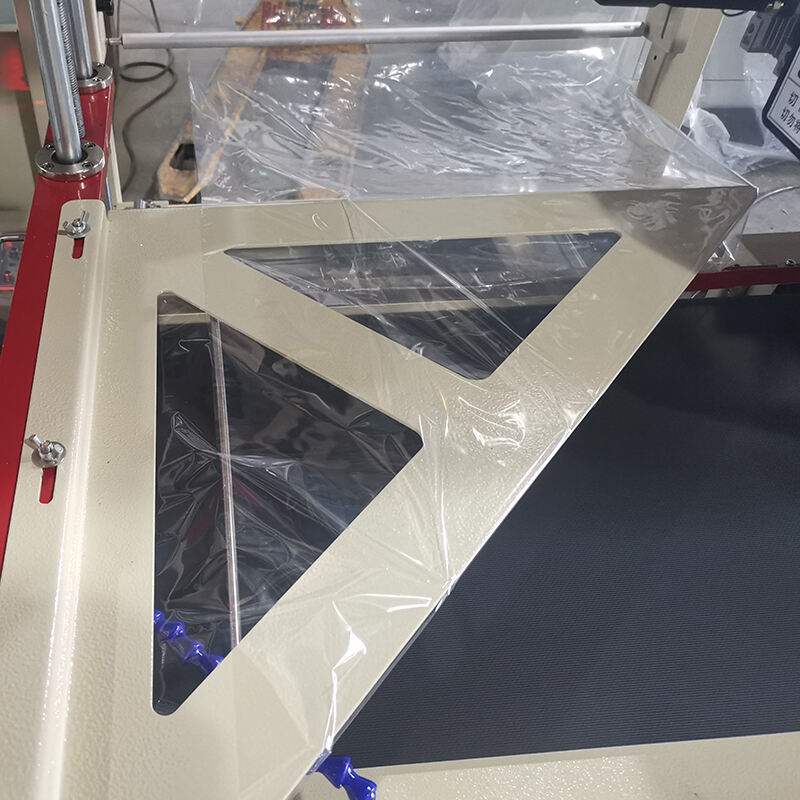

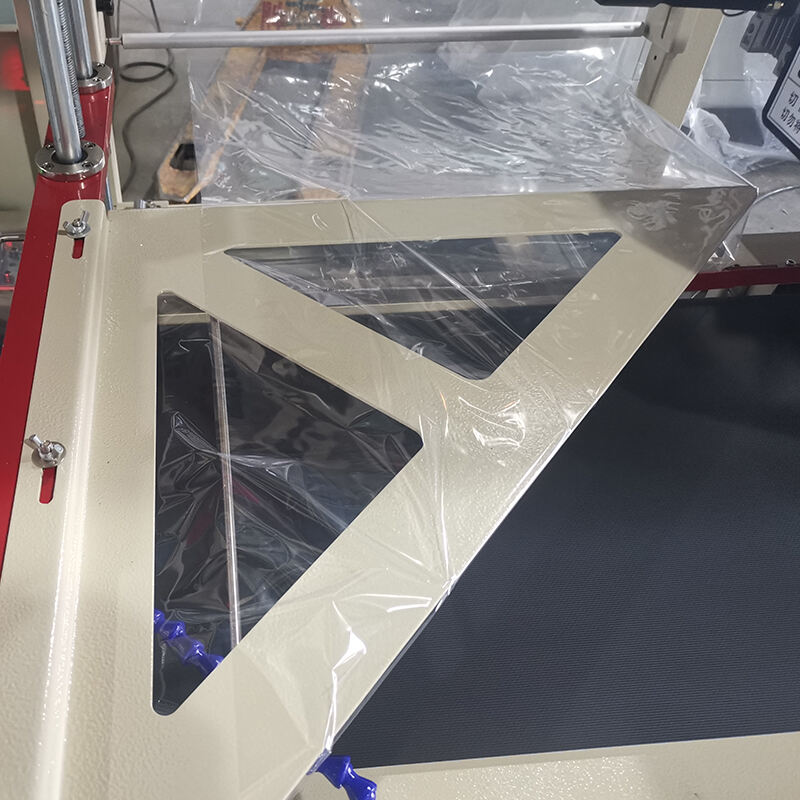

Film Folding Device - Folding Heat Shrink Film |

Controller - temperature and speed setting for heat sealing after folding and counting |

|

|

Scrap Recycling-Cutting and collection of trimmings after folding. |

Heater - heating and shrinking of the wrapping film |