ST-600T Box-type (Soft drawn Roll paper)Automatic Handle Pasting Machine

Suitable for box drawer, soft drawer, kitchen roll, small tray paper, etc.

In the package of automatic sticking handle, set of film feeding, cutting, film, sealing, lifting a complete set of packaging forms,

Compact and reasonable structure, simple operation and adjustment.

- Overview

- Recommended Products

Product Description

It is suitable for pasting handle of box facial tissue, kitchen roll, toilet roll etc.

Machine Performance and Parameters

| ltem/model | ST-600T |

| Handle material | PET spread with adhesive tape on both sides |

| Film roll specification | Odф≤280mm, paper core lD ф76mm width≤400mm |

| Packing specification | L≤700mm×W≤260mm×H≤130mm |

| Production capacity | 5-50packs/min |

| Handle width | 20-50mm |

| Power | Three-phase four-wire 380V 50Hz 1.0KW |

| Air supply | 0.5-0.8Mpa |

| Air consumption | 60-100L/min |

| Outline dimensions | L1990×W1100×H1780mm |

| Machine weight | 900kg |

Packing Style and Specification

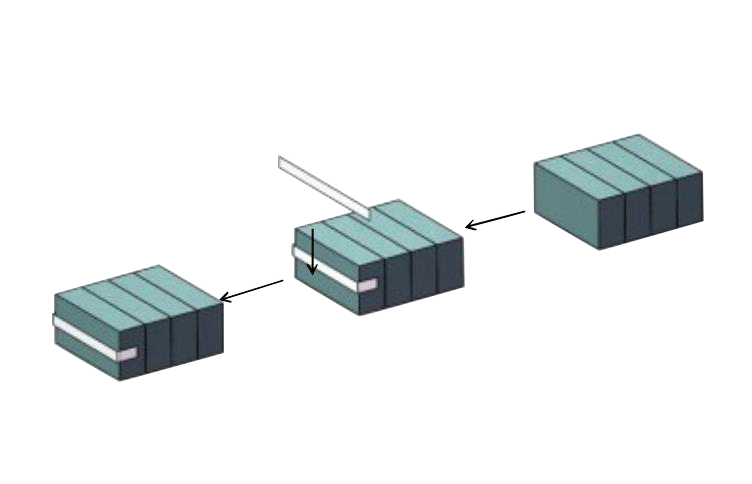

1、Flow Chart

2、Real Example

Main Features and Advantages

1、Packing forms such as automatic material feeding, film feeding, slitting,handle feeding, handle fixing,etc.are adopted. Featured by compact and reasonable structure, simple operation and adjustment.

2、Servo, touch screen, PLC control system and man-machine interface display make operation more clear and convenient.With high automation degree,the machine is more user-friendly.

3、The automatic material arranging and conveying mechanism is adopted to facilitate linked production with the automatic production line, which can greatly reduce labor cost.

4、The photoelectric eye automatic detection tracking system is adopted. No handle feeding is made is made if there is no material, so as to save packing materials to the utmost extent.

5、With wide packing range and convenient adjustment, fast switching among various specifications and sizes can be realized.

6、Change of specifications does not need change of molds, but can be realizde Vthrough adjustment.

7、Hande width can be adjusted and set according to customer needs.

8、Hot handle fixing can be adopted according to customer requirements.

Equipment Details

|

||

| Automatic material feeding conveyor-With photoelectricity measuring material, after the last material reaches the position, then convey the next one to avoid collision failure. | Material pusher-Push materials to the next production step to avoid collision failures | Slitting and covering film unit-Automatic film feeding, accurate slitting and covering of film, guaranteeing no air bubbles and folds. |

|

|

| Handle mounting device - adding handles to products after heat shrink packaging | Finished product output-Packaging finished products is convenient for customers to carry and enhance the humanized design of the product. |