STZ-260 Oral Liquid Cartoning Machine

Vital automation equipment for pharmaceutical production lines,

Dramatically improving productivity and packaging quality consistency,

Designed for efficient and accurate loading of vials, blister packs, tubes, instructions, etc. Into gmp-compliant cartons.

- Overview

- Recommended Products

Product Description

STZ-260 is a fully automatic multifunctional cartoning machine; the whole machine shell is made of 304 stainless steel and 10MM thick transparent plexiglass, the appearance of the beautiful neat and classy. This machine applies to a wide range of areas: all aspects of life: such as daily necessities, cosmetics, food, pharmaceuticals, hardware, health care products from all walks of life products cartoning and sealing, etc. (specifications for the size of the equipment, please refer to technical parameters)

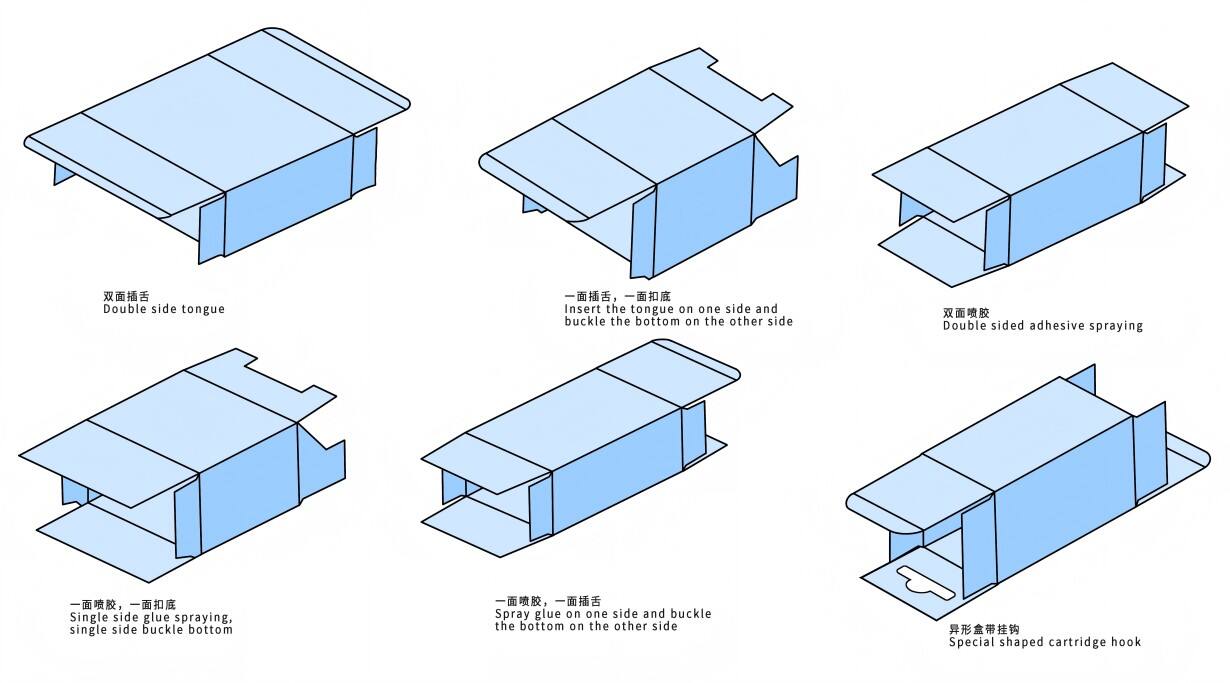

Suitable Carton Type:

Machine Performance and Parameters

| Model | STZ-260 |

| Carton material requirements | 280-350g/m2(Depending on the size of the carton) |

| Packing specifications | L150-350mm×W180-260mm×H30-120m |

| Packing speed | 30-70boxes/min |

| Main motor power | 2kw |

| Power source | 2kw |

| Power supply type | 380V 50HZ/60HZ |

| Machine noise | ≦80dB |

| Compressed air pressure | 0.5-0.8Mpa |

| Air consumption | 120-160L/min |

| Machine size | 5186mmx1560mmx1905mm |

| Machine weight | 2500kg |

Packing Style and Specification

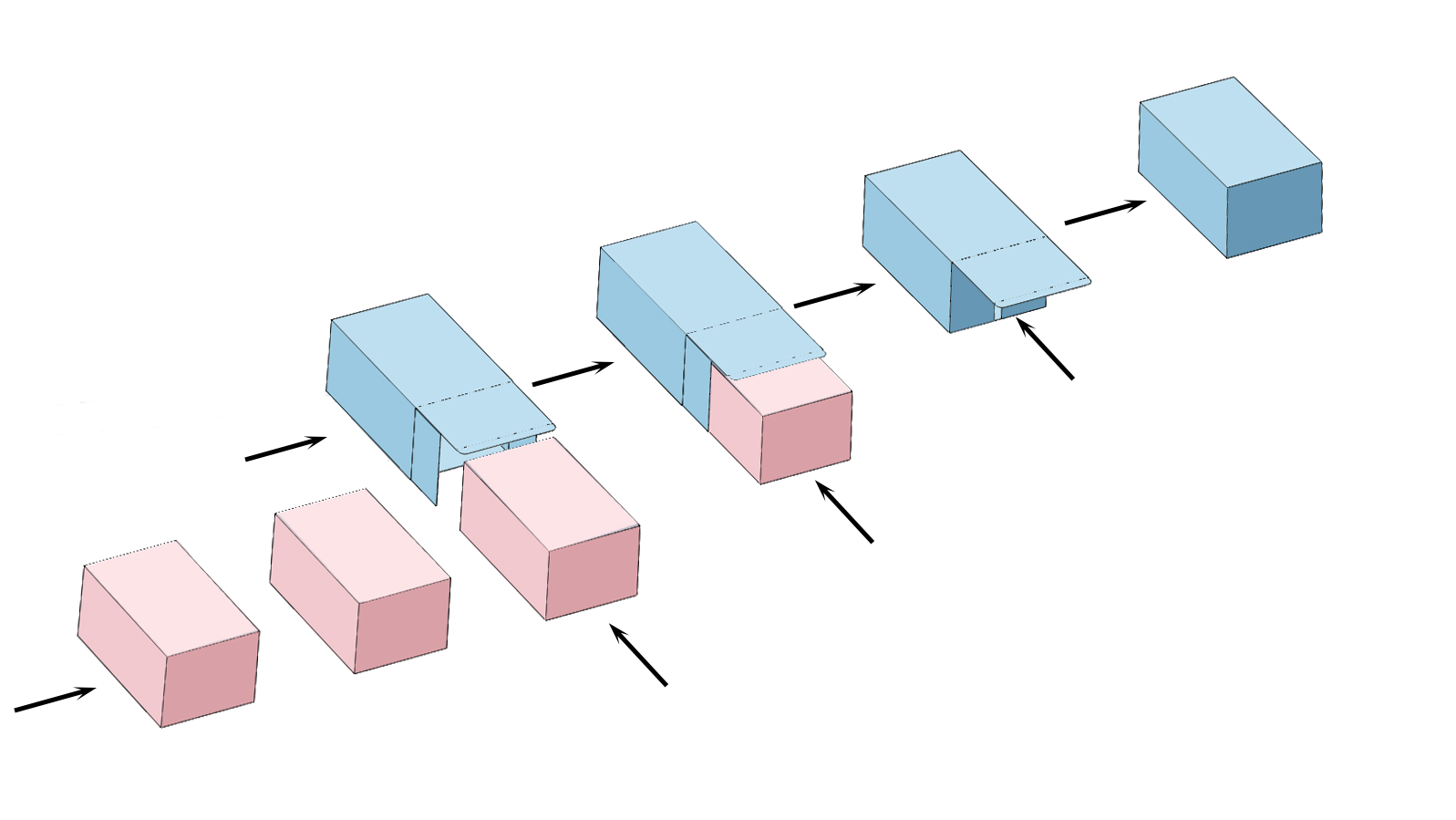

1、 Flow Chart

2、Real Example

|

|

|

Main Features and Advantages

1、Automatic opening (sucking) box, folding instruction manual, blanking, feeding, marking batch number, sealing box, testing and weeding are adopted, with stable operation and low noise.

2、PLC and man-machine interface automatic control operating system, stepless frequency conversion speed regulation, high degree of automation, easy to understand operation.

3、Adopt international famous brand electrical components, stable and reliable performance.

4、Automatic stop function of mechanical overload is adopted to ensure the safety of human and machine.

5、Automatically remove the packaging products that are short of packing materials or instructions to ensure the quality of the packaging products.

6、It has the functions of fault display, alarm and finished product counting, which is convenient for maintenance and troubleshooting.

7、Various automatic feeders and conveying mechanisms can be designed according to customer requirements.

8、Hot melt adhesive machine can be used. Hot melt glue spraying sealing or hot melt glue brushing device can be designed.

9、It can be connected with aluminum plastic packaging machine, pillow type packaging machine, filling machine, soap making machine, code spraying machine (or supervision code system), labeling machine, online weighing instrument, cellophane over packaging machine, shrink wrapping machine, strapping machine and other production lines.

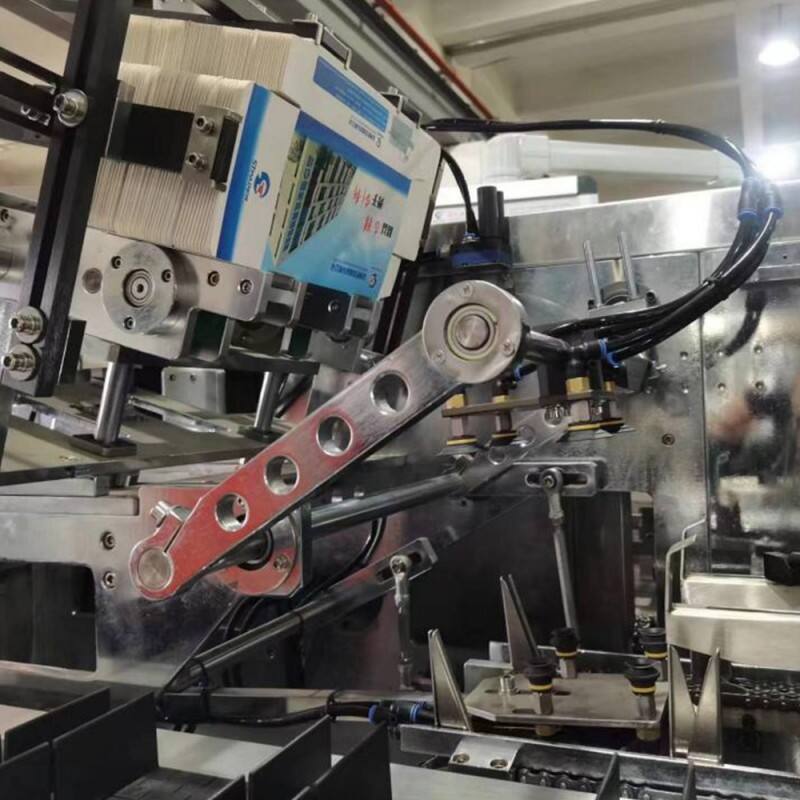

Equipment Details

|

|

|

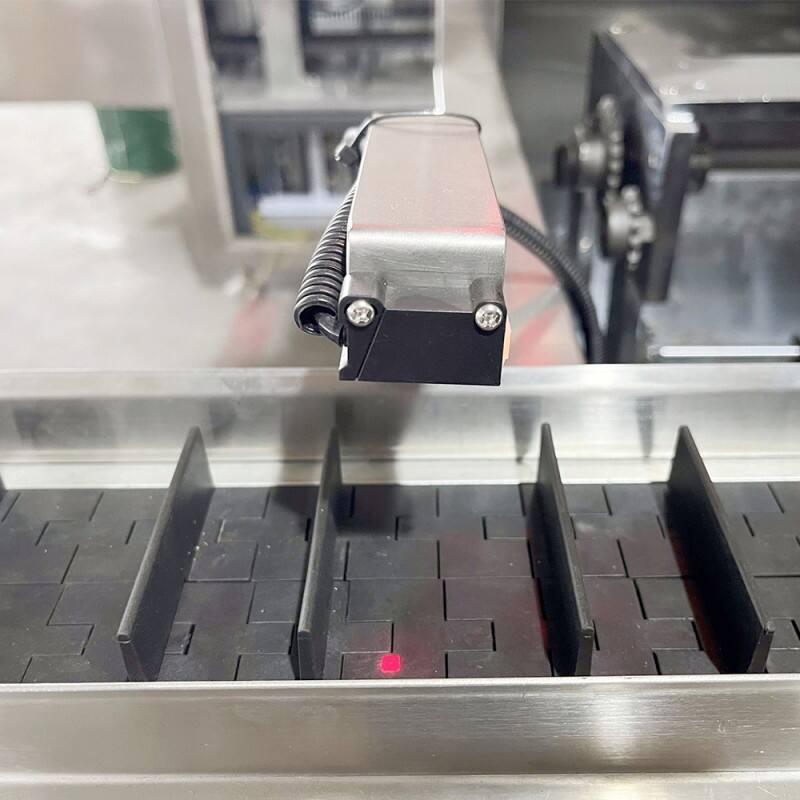

Conveyor Belt - Adjustable length of the material bin according to the demand, with photoelectric detection function, in line with the industry requirements |

Carton storage bin-With detection photoelectricity, automatic forward lower carton, less carton alarm |

Upper and lower suction box-Automatically opens the box and waits for the material to enter |

|

|

|

Upper pressing box cylinder - one button to lift up, easy to adjust the box specifications |

Tongue insertion mechanism-automatic tongue insertion and sealing, also can be equipped with glue spraying and bottom buckling device |

Finished product output-Failed products are detected by photoelectricity and can be rejected here to guarantee 99.9% pass rate |