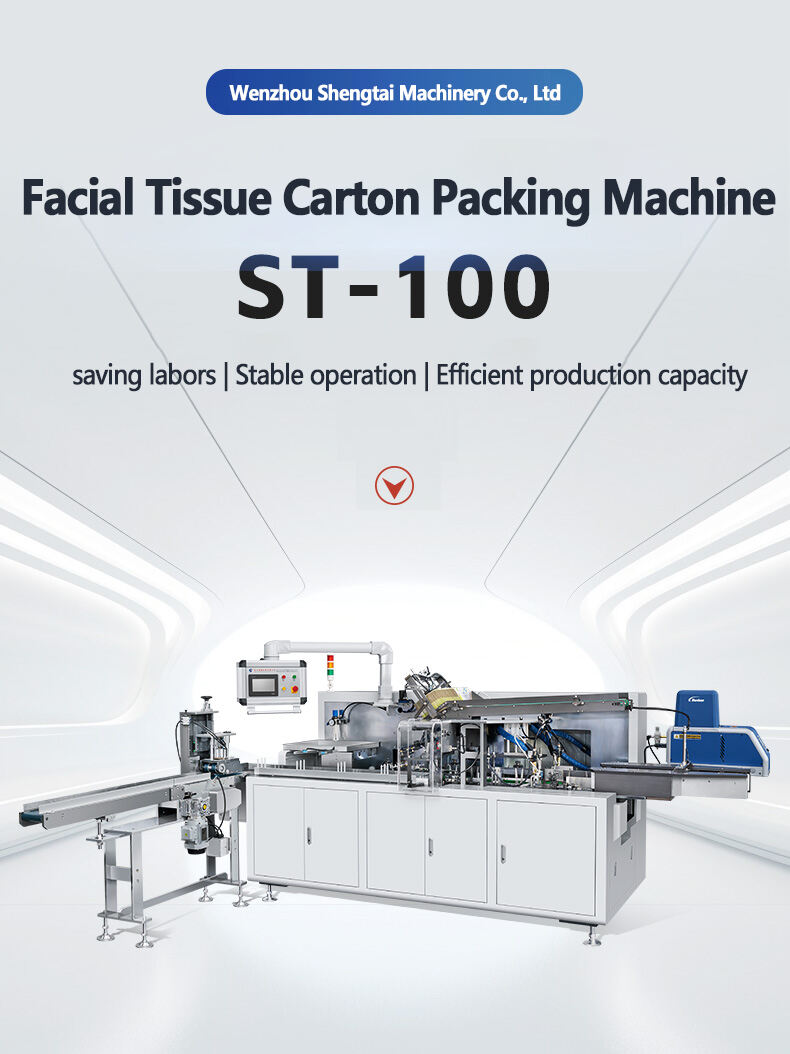

multifunction cartoning machine

The multifunction cartoning machine represents a pinnacle of modern packaging automation, combining versatility and precision in a single unit. This advanced machinery seamlessly integrates multiple packaging processes, including carton forming, product insertion, and sealing, all within one efficient system. The machine utilizes sophisticated servo motor technology to ensure precise control and consistent operation across various packaging tasks. Its modular design accommodates different carton sizes and styles, making it ideal for diverse product lines in pharmaceuticals, food, cosmetics, and consumer goods industries. The machine features an intuitive HMI interface that allows operators to easily adjust settings and monitor performance in real-time. With processing speeds of up to 120 cartons per minute, it significantly enhances production efficiency while maintaining high accuracy levels. The system incorporates advanced safety features, including emergency stop functions and protective guards, ensuring operator safety without compromising accessibility for maintenance. Additionally, its compact footprint optimizes floor space utilization while delivering comprehensive packaging solutions.