paper quilling cutting machine

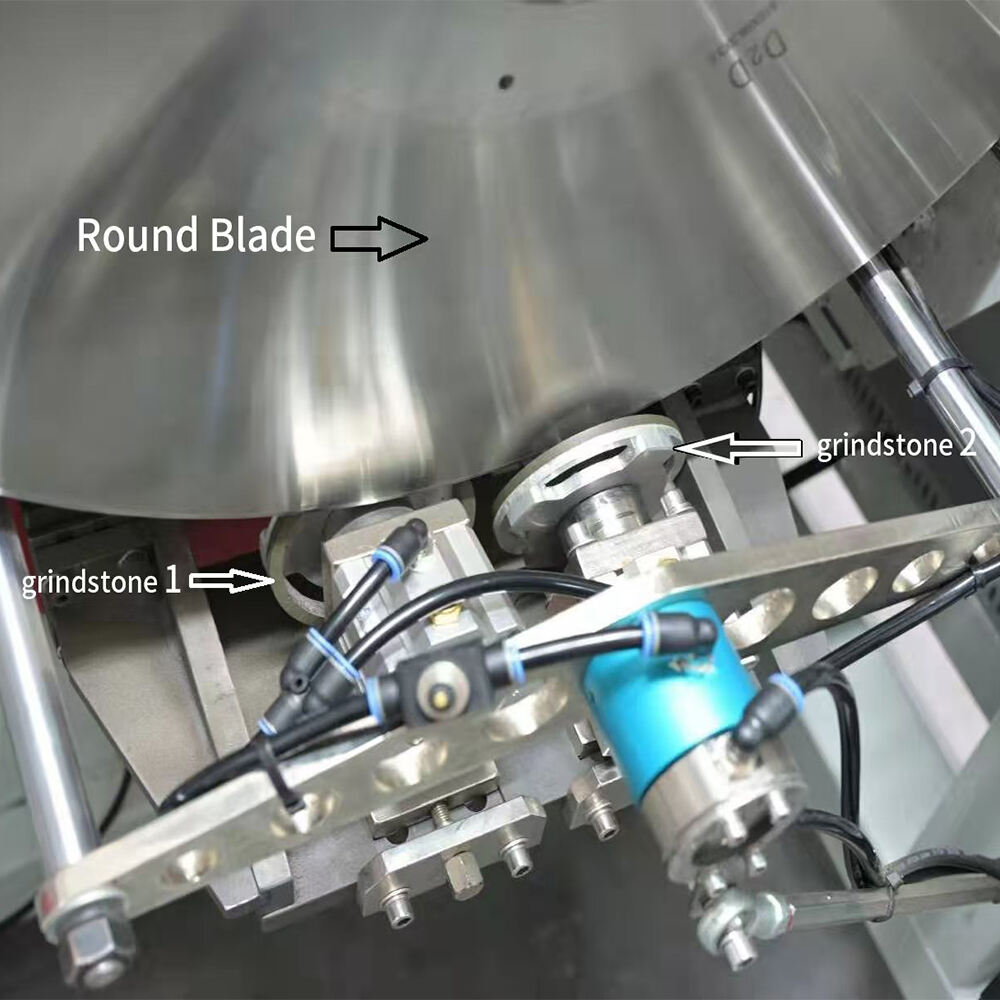

The paper quilling cutting machine represents a significant advancement in paper craft technology, offering precision and efficiency for both hobbyists and professional artists. This innovative device automatically cuts paper strips to exact widths and lengths, ensuring consistency in quilling projects. The machine features adjustable cutting settings, allowing users to create strips ranging from 1mm to 10mm in width, with length customization options up to 500mm. It incorporates high-grade stainless steel blades that deliver clean, precise cuts without fraying or damaging the paper. The digital control panel enables users to program specific measurements and quantities, streamlining the preparation process for large-scale projects. Additionally, the machine includes safety features such as an automatic shut-off mechanism and blade guards. Its compact design makes it suitable for home studios and craft rooms, while its durable construction ensures long-term reliability. The machine can handle various paper weights, from lightweight quilling paper to cardstock, making it versatile for different project requirements.