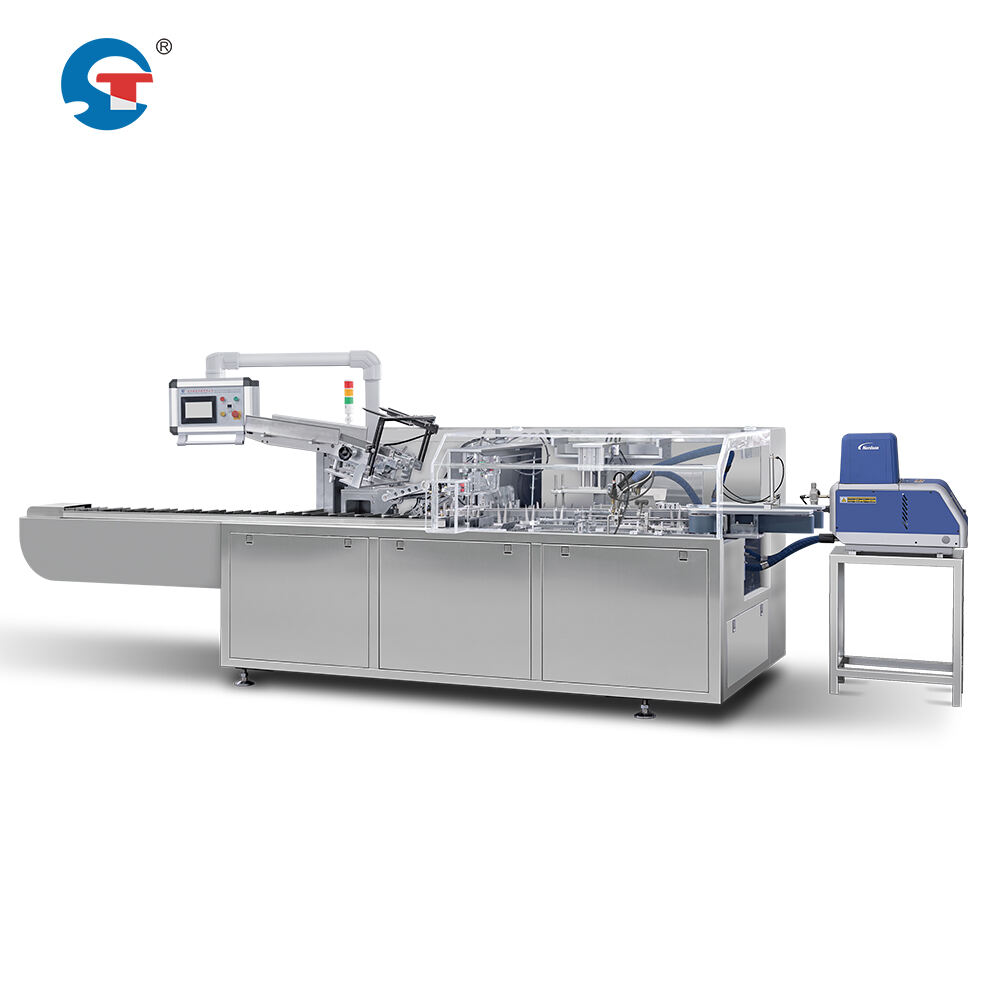

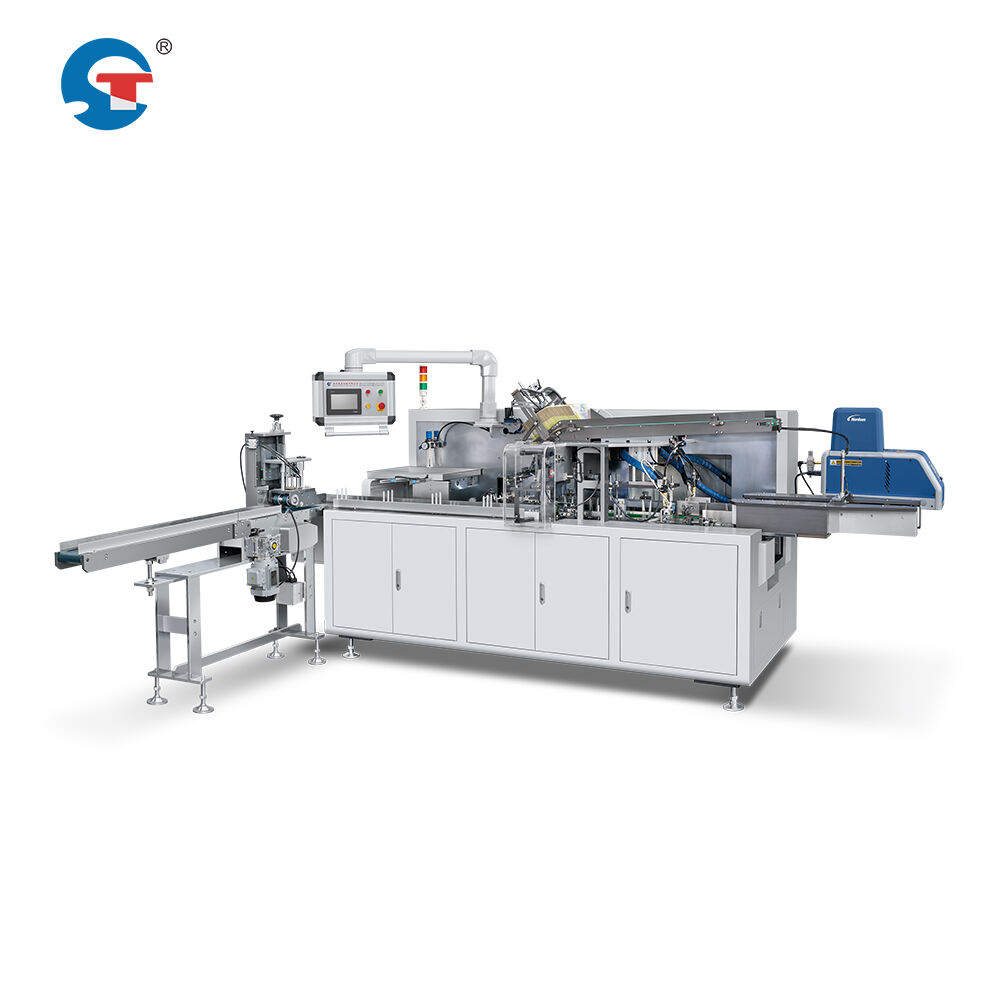

stationery cartoning machine

The stationery cartoning machine represents a cutting-edge solution for automated packaging in the stationery industry. This sophisticated equipment efficiently handles various stationery items, from pens and pencils to office supplies, automatically inserting them into cartons or boxes with precision and speed. The machine incorporates advanced servo motor technology, enabling accurate product placement and consistent packaging quality. Its modular design allows for flexible configuration based on specific packaging requirements, while the integrated PLC control system ensures seamless operation and real-time monitoring. The machine features multiple feeding stations that can handle different product types simultaneously, making it ideal for mixed product packaging. With adjustable carton sizes and product accommodation capabilities, it offers versatility for various stationery items. The system includes automatic carton forming, product insertion, and sealing mechanisms, significantly reducing manual labor requirements. Safety features such as emergency stop buttons and transparent safety guards ensure operator protection while maintaining optimal production efficiency. The machine's robust construction using stainless steel and high-quality materials guarantees durability and long-term reliability in industrial settings.