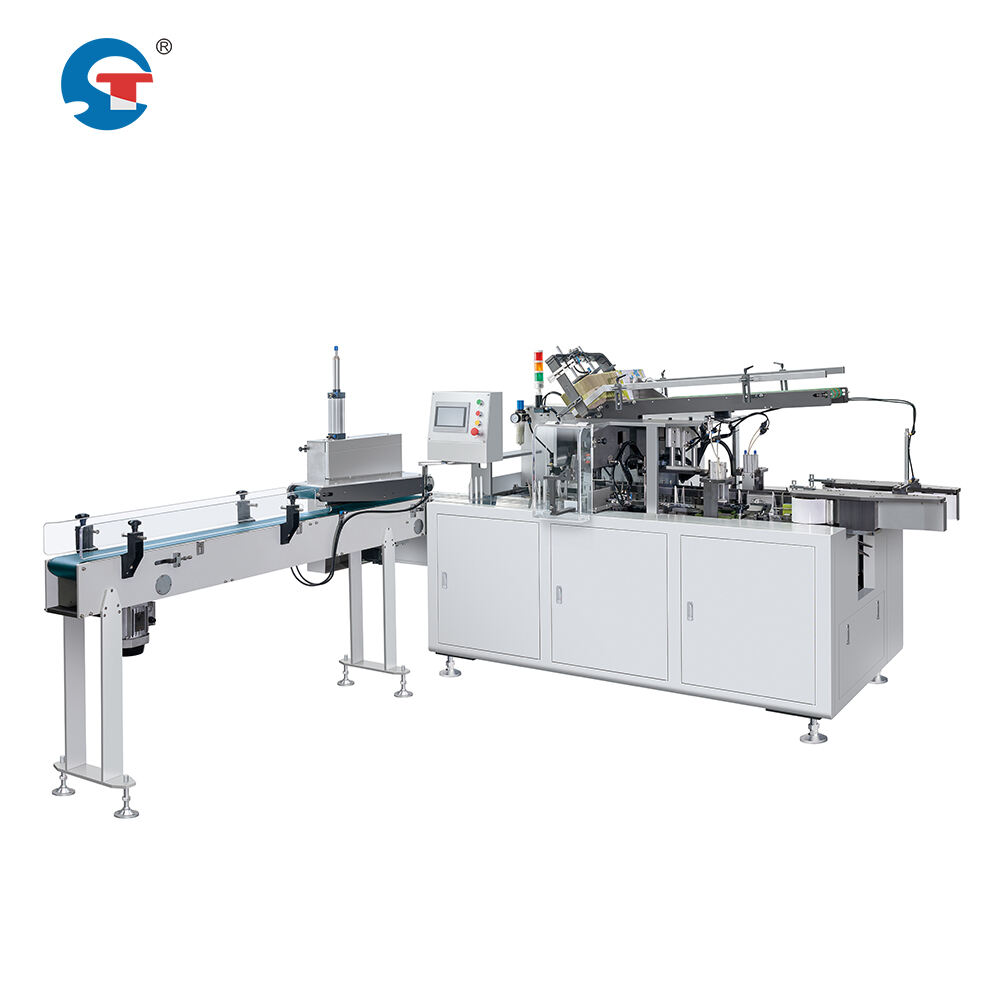

candy fully automatic cartoning machine

The candy fully automatic cartoning machine represents a state-of-the-art solution for efficient packaging operations in the confectionery industry. This advanced machinery seamlessly integrates multiple functions, including product feeding, carton erecting, product insertion, and carton sealing, all in one continuous automated process. The machine features precision servo controls and intelligent PLC systems that ensure accurate timing and synchronization across all operations. With processing speeds of up to 120 cartons per minute, it significantly enhances production efficiency while maintaining consistent quality. The machine accommodates various candy types and packaging formats, from small individually wrapped pieces to larger assorted boxes. Built with food-grade stainless steel construction, it meets stringent hygiene standards and features tool-less changeover capabilities for different product sizes. The user friendly interface allows operators to monitor and adjust parameters in real time, while the integrated safety systems ensure workplace security. Advanced sensors throughout the system provide continuous quality control, detecting any anomalies in carton formation or product placement. The machines modular design facilitates maintenance and cleaning, reducing downtime and extending operational life.