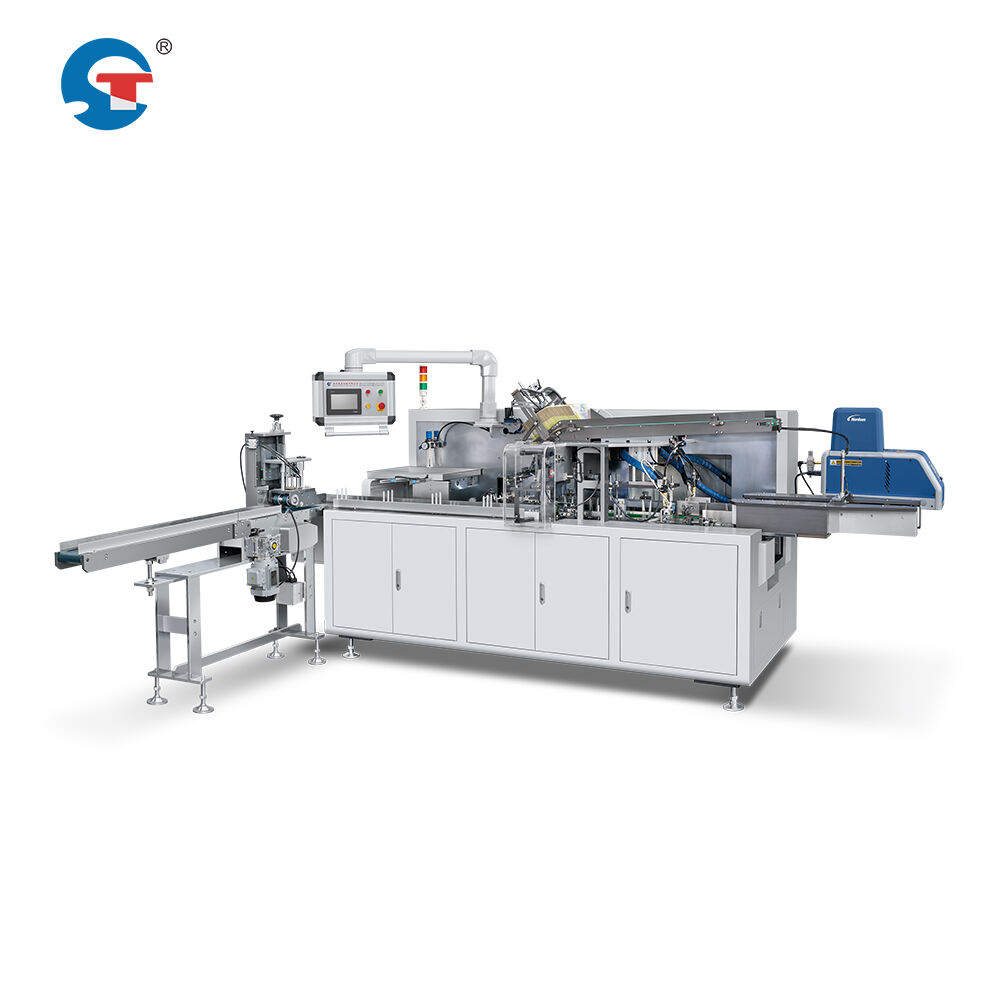

chocolate fully automatic cartoning machine

The chocolate fully automatic cartoning machine represents a state-of-the-art solution for packaging operations in the confectionery industry. This advanced equipment streamlines the entire packaging process, handling everything from carton forming and product loading to sealing and coding. The machine operates through a sophisticated servo control system that ensures precise movements and consistent performance, capable of processing up to 120 cartons per minute depending on the model and product specifications. It features an intelligent feeding system that carefully handles chocolate products, maintaining their integrity while efficiently placing them into cartons. The machine accommodates various carton sizes and styles, making it versatile for different product lines. Its stainless steel construction meets food industry standards, while the user-friendly HMI interface allows for easy operation and quick format changes. The system includes automatic quality control mechanisms that verify carton integrity and proper product placement, reducing waste and ensuring high-quality output. Advanced safety features protect operators while maintaining optimal production speeds, and the machines modular design facilitates maintenance and cleaning procedures.