Revolutionizing Product Protection Through Advanced Packaging Technology

In today's competitive manufacturing and distribution landscape, protecting products during storage and transit has become more crucial than ever. Shrink wrap machines have emerged as a game-changing solution, offering unprecedented levels of protection while streamlining packaging operations. These innovative systems have transformed how businesses approach product security, presentation, and preservation across various industries.

The evolution of packaging technology has led to more sophisticated and efficient shrink wrap machines that cater to diverse business needs. From small-scale operations to large industrial facilities, these machines provide a reliable method for securing products against environmental factors, tampering, and damage during handling and transportation.

Core Advantages of Modern Packaging Systems

Enhanced Product Protection and Security

Shrink wrap machines create a tight, protective barrier around products, effectively shielding them from dust, moisture, and physical damage. This sealed environment prevents contamination and maintains product integrity throughout the supply chain. The durable film creates a tamper-evident package, giving both manufacturers and consumers peace of mind regarding product safety and authenticity.

The protective layer formed by these machines also helps prevent theft and unauthorized access, making it an ideal solution for retail-ready packaging. Products wrapped using professional shrink wrap machines maintain their original condition from production to final delivery, reducing the risk of returns and customer complaints.

Operational Efficiency and Cost Reduction

Implementing shrink wrap machines in packaging operations leads to significant improvements in productivity and cost management. These systems can process multiple items simultaneously, dramatically reducing the time and labor required compared to manual wrapping methods. The automated nature of shrink wrap machines ensures consistent packaging quality while minimizing material waste.

The economic benefits extend beyond immediate operational costs. By providing superior protection, these machines reduce product damage during transit, leading to fewer returns and replacements. Additionally, the compact nature of shrink-wrapped packages optimizes storage space and reduces transportation costs.

Professional Applications and Industry Impact

Versatility Across Different Sectors

From food and beverage to electronics and pharmaceuticals, shrink wrap machines demonstrate remarkable adaptability. Their ability to handle products of various sizes, shapes, and materials makes them invaluable across different industries. Food manufacturers particularly benefit from the protective barrier that maintains freshness and extends shelf life, while electronics manufacturers rely on these machines for protecting sensitive components.

The pharmaceutical industry utilizes shrink wrap machines for maintaining product sterility and ensuring compliance with stringent packaging regulations. Retail businesses appreciate the professional appearance and security features that shrink-wrapped packages provide, enhancing product presentation on store shelves.

Environmental Considerations and Sustainability

Modern shrink wrap machines are designed with environmental consciousness in mind. Many systems now accommodate eco-friendly films and recyclable materials, aligning with growing sustainability demands. The precise control over material usage reduces waste, while the durability of shrink-wrapped packages often eliminates the need for additional packaging layers.

Manufacturers can now choose from a range of biodegradable and recycled film options, maintaining product protection while reducing environmental impact. This adaptability helps businesses meet corporate sustainability goals and satisfy environmentally conscious consumers.

Technical Innovations and Future Developments

Advanced Control Systems and Automation

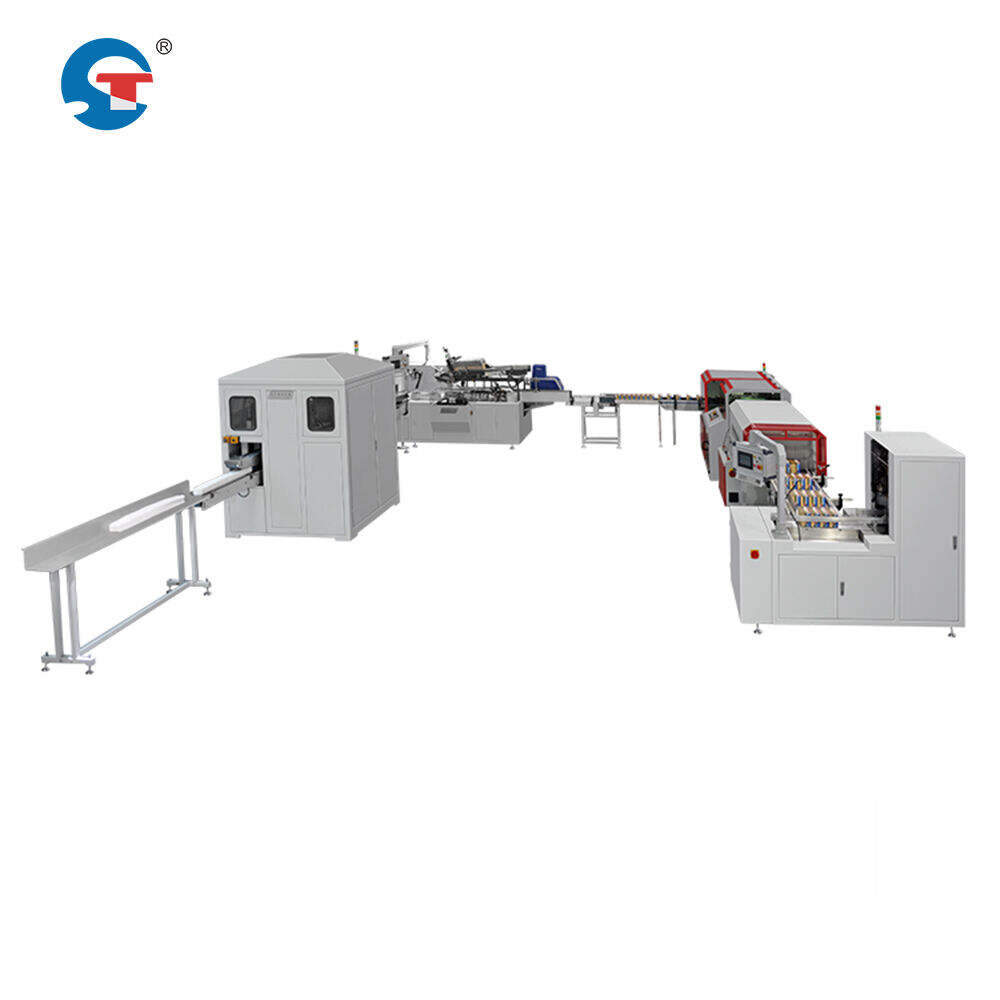

The latest generation of shrink wrap machines incorporates sophisticated control systems and automation features. Touch-screen interfaces, programmable settings, and remote monitoring capabilities make operation more intuitive and efficient. These technological advances enable precise control over wrapping parameters, ensuring optimal results for different product types.

Integration with production line management systems allows for seamless operation and real-time performance monitoring. Smart features such as automatic film tensioning and temperature control reduce operator intervention while maintaining consistent packaging quality.

Emerging Technologies and Market Trends

The shrink wrap machine industry continues to evolve with emerging technologies. Manufacturers are developing more energy-efficient systems with improved heating elements and control mechanisms. Innovation in film materials and application methods promises even better protection while reducing environmental impact.

Future developments may include AI-powered systems for optimal package customization and predictive maintenance capabilities. These advancements will further enhance the efficiency and versatility of shrink wrap machines, making them even more valuable for businesses of all sizes.

Frequently Asked Questions

How do shrink wrap machines improve packaging efficiency?

Shrink wrap machines automate the packaging process, significantly reducing labor costs and processing time. They provide consistent results with minimal waste, handling multiple products simultaneously while ensuring uniform protection and appearance.

What types of products can be protected using shrink wrap machines?

These versatile machines can handle a wide range of products, from small consumer goods to large industrial items. They're suitable for food products, electronics, pharmaceuticals, printed materials, and virtually any item requiring protective packaging.

Are shrink wrap machines environmentally friendly?

Modern shrink wrap machines are designed with environmental considerations in mind, supporting the use of recyclable and biodegradable films. They minimize material waste through precise control and can significantly reduce overall packaging material requirements.

What maintenance do shrink wrap machines require?

Regular maintenance typically includes cleaning heating elements, checking sealing components, and ensuring proper calibration of temperature controls. Most modern machines feature diagnostic systems that help identify maintenance needs and prevent operational issues.