Essential Maintenance Strategies for Packaging Equipment Excellence

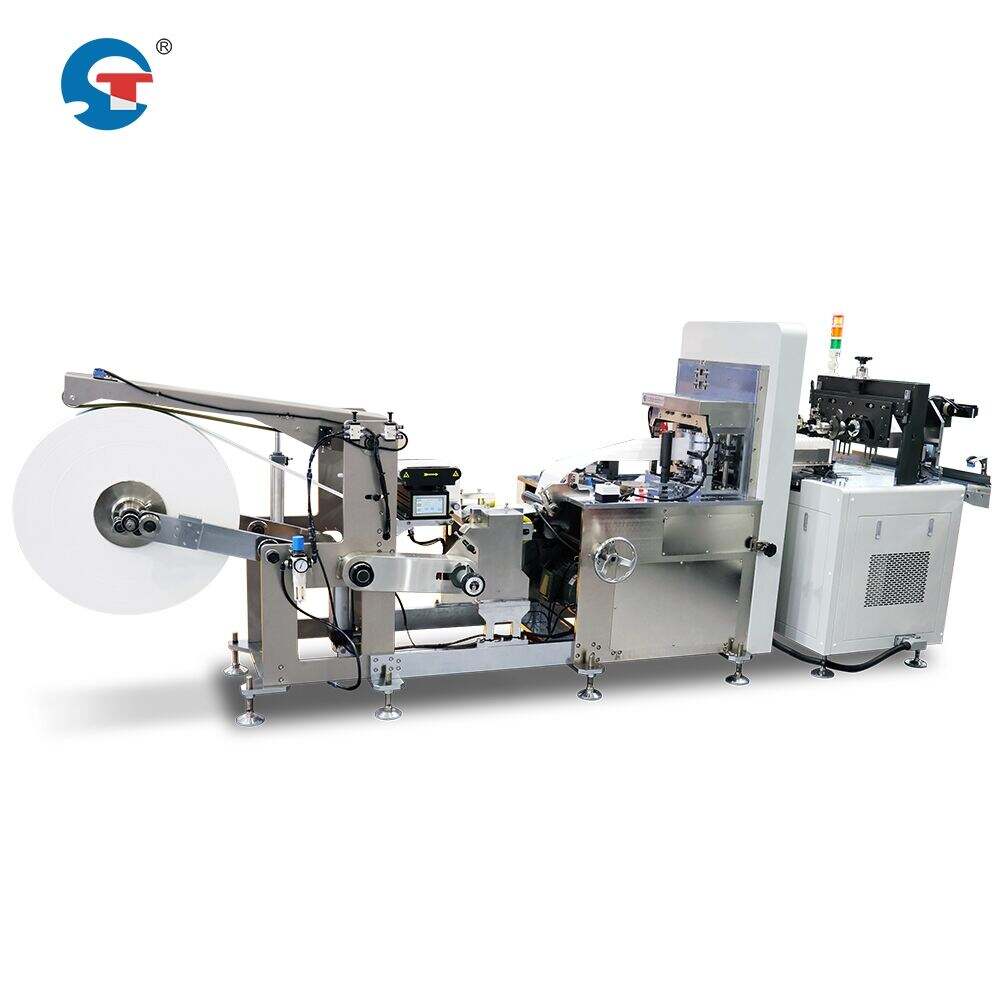

The success of any packaging operation heavily depends on the reliable performance of its horizontal cartoning machine. These sophisticated pieces of equipment represent a significant investment and form a crucial link in the production chain. Proper maintenance and optimization not only extend equipment lifespan but also ensure consistent packaging quality and minimize costly downtime.

Modern horizontal cartoning machines are engineering marvels that require systematic care and attention to maintain their precision and efficiency. By implementing comprehensive maintenance protocols, manufacturers can significantly improve operational efficiency while protecting their investment for years to come.

Preventive Maintenance Fundamentals

Daily Inspection and Cleaning Protocols

A robust maintenance routine begins with daily inspections of the horizontal cartoning machine. Operators should check for any unusual sounds, vibrations, or movements that might indicate developing issues. Regular cleaning of product contact surfaces, conveyor belts, and carton magazines prevents debris accumulation that could affect machine performance.

Implementation of a detailed cleaning schedule ensures all critical components remain free from dust, product residue, and other contaminants. Special attention should be given to lubrication points, drive mechanisms, and sensor surfaces to maintain optimal functionality.

Lubrication and Component Care

Proper lubrication is crucial for the smooth operation of a horizontal cartoning machine. Following manufacturer-specified lubrication schedules and using recommended lubricants helps prevent wear and extends component life. Key areas requiring regular lubrication include chain drives, bearings, and sliding mechanisms.

Component care extends beyond lubrication to include regular inspection of wear parts such as timing belts, conveyor chains, and carton forming elements. Establishing a comprehensive parts inventory and replacement schedule prevents unexpected breakdowns and maintains consistent machine performance.

Performance Optimization Techniques

Speed and Timing Adjustments

Optimal performance of a horizontal cartoning machine depends on precise timing and speed settings. Regular calibration of timing mechanisms ensures smooth product flow and accurate carton formation. Speed adjustments should be made based on product characteristics and production requirements while maintaining consistent quality.

Machine operators should document optimal settings for different product types and packaging configurations. This documentation serves as a valuable reference for maintaining consistent performance across different production runs and shift changes.

Quality Control Integration

Integration of quality control measures into the maintenance routine helps identify potential issues before they affect production. Regular checks of carton formation, glue application, and closing mechanisms ensure consistent package quality. Implementation of systematic quality monitoring procedures helps maintain high standards while minimizing waste.

Advanced horizontal cartoning machines often include built-in quality control features that should be regularly calibrated and maintained. These may include vision systems, weight checks, or code verification equipment that contribute to overall package quality.

Advanced Maintenance Strategies

Predictive Maintenance Implementation

Modern horizontal cartoning machines benefit from predictive maintenance approaches that utilize data analytics and sensor technology. Monitoring key performance indicators helps identify potential issues before they lead to failures. Implementation of predictive maintenance strategies can significantly reduce unplanned downtime and maintenance costs.

Integration of condition monitoring systems provides real-time insights into machine health and performance trends. This data-driven approach enables maintenance teams to schedule interventions at optimal times, minimizing production disruptions while maximizing equipment reliability.

Software and Control System Updates

Regular updates to machine control systems and software ensure optimal performance and access to the latest features. Maintaining current software versions can improve efficiency, reduce errors, and enhance safety features. Scheduling regular system backups and updates prevents compatibility issues and maintains system integrity.

Working closely with equipment manufacturers to implement recommended software updates and system improvements helps maximize the capabilities of the horizontal cartoning machine while ensuring long-term reliability.

Training and Documentation

Operator Training Programs

Comprehensive operator training is essential for maintaining optimal machine performance. Regular training sessions should cover basic maintenance procedures, troubleshooting techniques, and best practices for machine operation. Well-trained operators can identify potential issues early and respond appropriately to prevent major problems.

Development of detailed operating procedures and maintenance checklists helps standardize practices across shifts and ensures consistent machine care. Regular refresher training keeps operators updated on new maintenance techniques and machine features.

Maintenance Record Keeping

Accurate documentation of maintenance activities, repairs, and machine performance provides valuable historical data for optimization efforts. Maintaining detailed records helps identify patterns, predict maintenance needs, and justify equipment upgrades when necessary. Electronic maintenance management systems can streamline record keeping and improve data accessibility.

Regular review of maintenance records helps identify recurring issues and opportunities for improvement in maintenance procedures. This data-driven approach supports continuous improvement efforts and helps optimize maintenance schedules.

Frequently Asked Questions

How often should a horizontal cartoning machine undergo complete maintenance?

A comprehensive maintenance schedule typically includes daily cleaning and inspections, weekly lubrication checks, monthly component inspections, and quarterly thorough maintenance reviews. Annual or semi-annual complete overhauls are recommended depending on usage intensity and operating conditions.

What are the signs that indicate a horizontal cartoning machine needs immediate attention?

Key warning signs include unusual noises, vibrations, decreased production speed, inconsistent carton formation, increased product waste, and quality issues in the finished packages. Any significant changes in normal operating parameters should be investigated promptly.

How can operators maximize the efficiency of a horizontal cartoning machine?

Operators can optimize efficiency by maintaining proper cleaning schedules, ensuring correct machine settings for each product type, performing regular calibrations, maintaining adequate spare parts inventory, and following manufacturer-recommended maintenance procedures. Regular training and adherence to standard operating procedures are also crucial for maximizing efficiency.