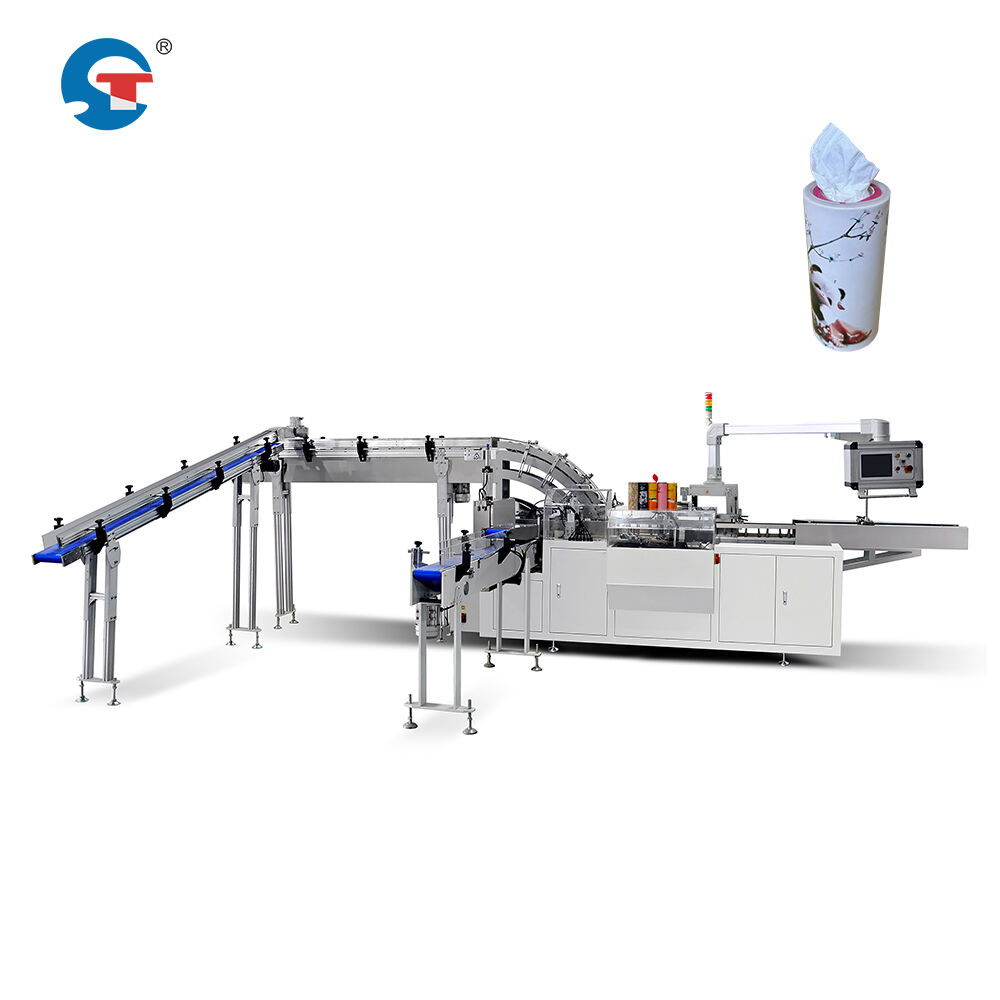

automatic cartoners and tray packers

Automatic cartoners and tray packers represent advanced packaging solutions designed to streamline and automate the process of product packaging. These sophisticated machines efficiently handle various packaging tasks, from forming and loading cartons to sealing and coding them. The systems utilize precision engineering to accommodate different product sizes and packaging requirements, operating at high speeds while maintaining consistent quality. Modern cartoners feature servo-driven mechanisms that ensure accurate product placement and gentle handling, while advanced control systems enable seamless integration with existing production lines. The equipment can process multiple package styles, including regular slotted containers, retail-ready packaging, and display trays. Key technological features include automated carton erecting, product loading mechanisms, precision folding systems, and quality control measures such as barcode verification and missing product detection. These machines find widespread applications across industries, including food and beverage, pharmaceuticals, cosmetics, and consumer goods. Their modular design allows for future upgrades and modifications to meet evolving packaging needs, while built-in safety features protect operators and maintain production efficiency. The systems can handle various materials, from paperboard to corrugated containers, and can be configured for different closure methods including hot melt glue, tuck-in flaps, or mechanical locking.