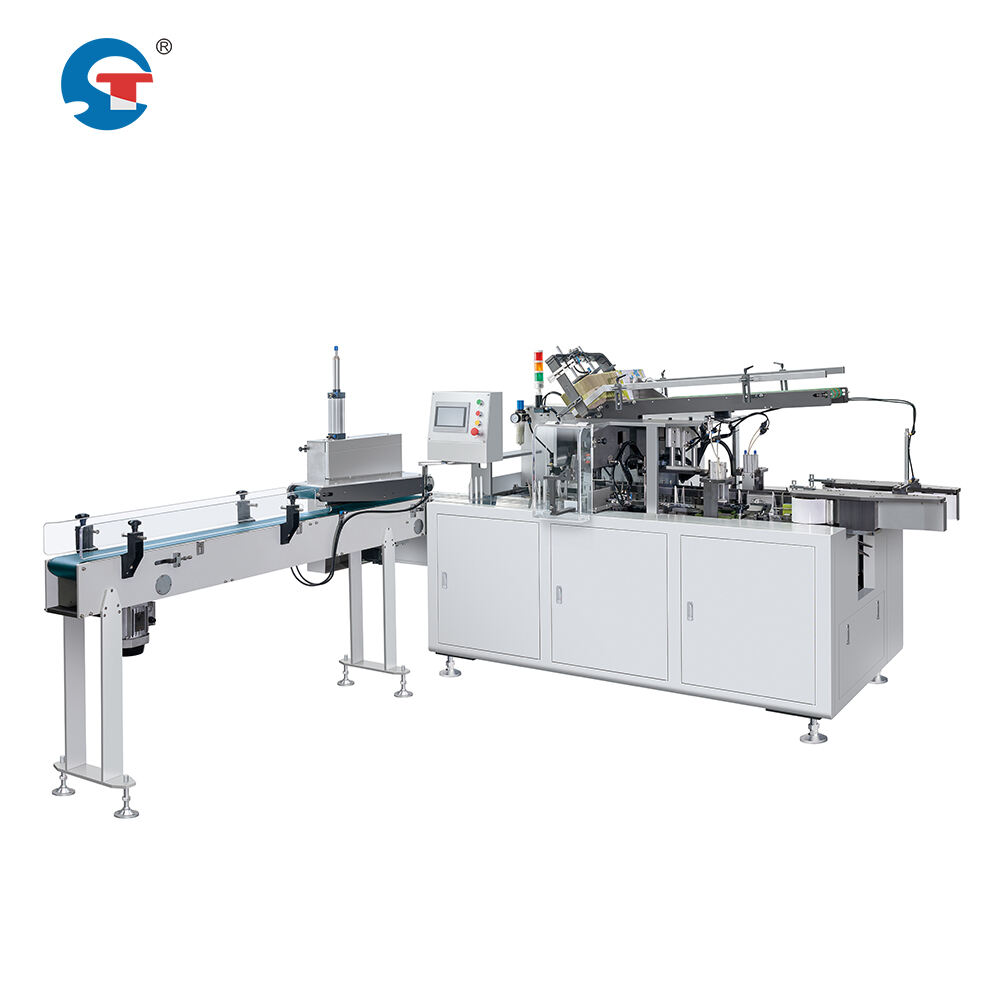

electronics cartoning machine

The electronics cartoning machine represents a sophisticated automated packaging solution designed specifically for the electronics industry. This advanced machinery efficiently handles the intricate process of packaging electronic components, circuit boards, and various electronic products into cartons or boxes. The machine integrates multiple functions including product feeding, carton forming, product insertion, and carton sealing in a single streamlined system. Operating with precision servo motors and advanced control systems, it achieves high accuracy in product handling while maintaining optimal production speeds of up to 120 cartons per minute. The machine's modular design allows for flexible configuration based on specific packaging requirements, accommodating different carton sizes and styles. Its smart detection system ensures proper product orientation and prevents damage to sensitive electronic components during the packaging process. The machine features a user-friendly HMI interface that enables easy operation and quick format changes, making it suitable for both small batch production and high-volume manufacturing. Additionally, it incorporates safety features such as emergency stops and protective guards to ensure operator safety while maintaining efficient production flow.