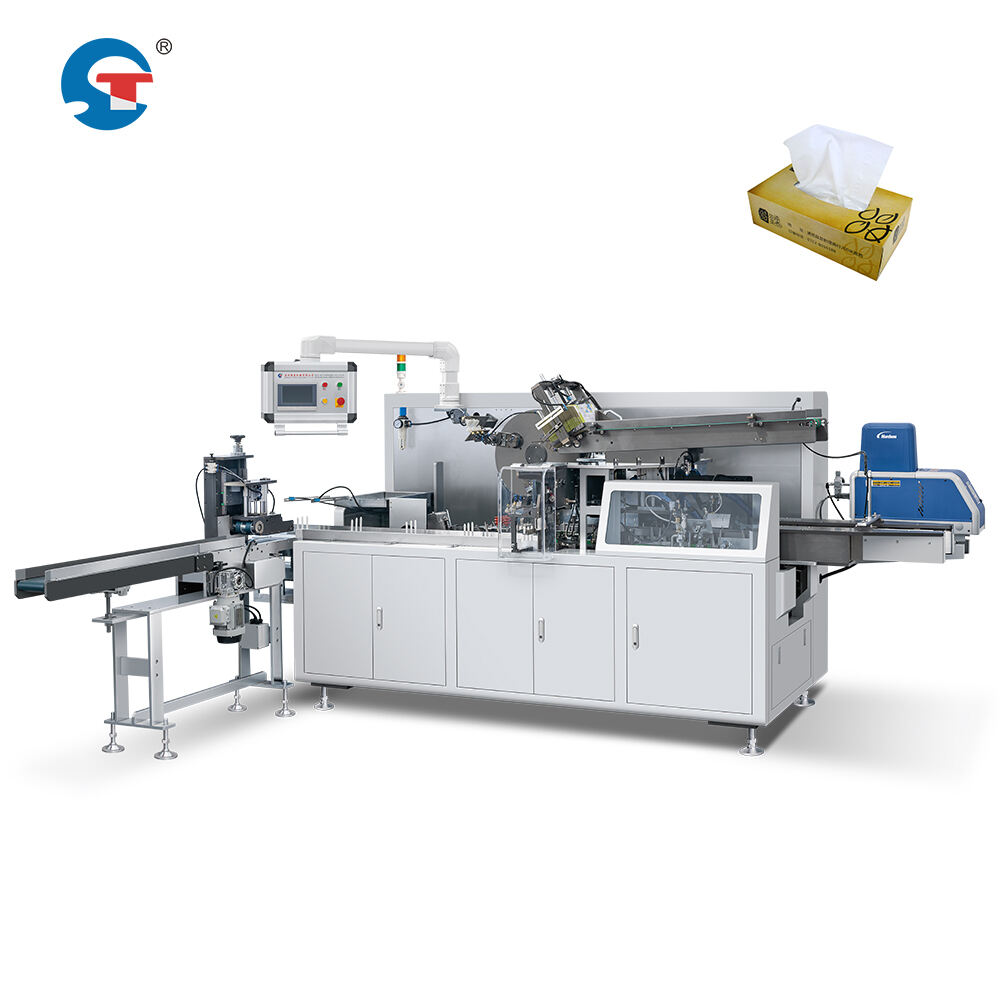

automated packaging machine

The automated packaging machine represents a pinnacle of modern industrial efficiency, combining precision engineering with advanced automation technology. This sophisticated system handles multiple packaging processes, from product sorting and alignment to sealing and labeling, all within a single integrated platform. At its core, the machine utilizes smart sensors and programmable logic controllers (PLC) to ensure accurate product handling and consistent packaging quality. The system can accommodate various package sizes and materials, making it versatile enough for industries ranging from food and beverage to pharmaceuticals and consumer goods. With processing speeds capable of handling hundreds of units per minute, these machines significantly boost production capacity while maintaining exceptional accuracy rates above 99%. The technology incorporates real-time monitoring systems that track performance metrics and automatically adjust operations to maintain optimal efficiency. Advanced features include automatic fault detection, self-diagnostic capabilities, and remote monitoring options that enable proactive maintenance. The machine's modular design allows for easy customization and future upgrades, ensuring long-term adaptability to changing production needs. Safety features such as emergency stops, guard interlocks, and protective enclosures ensure operator protection while maintaining high productivity levels.