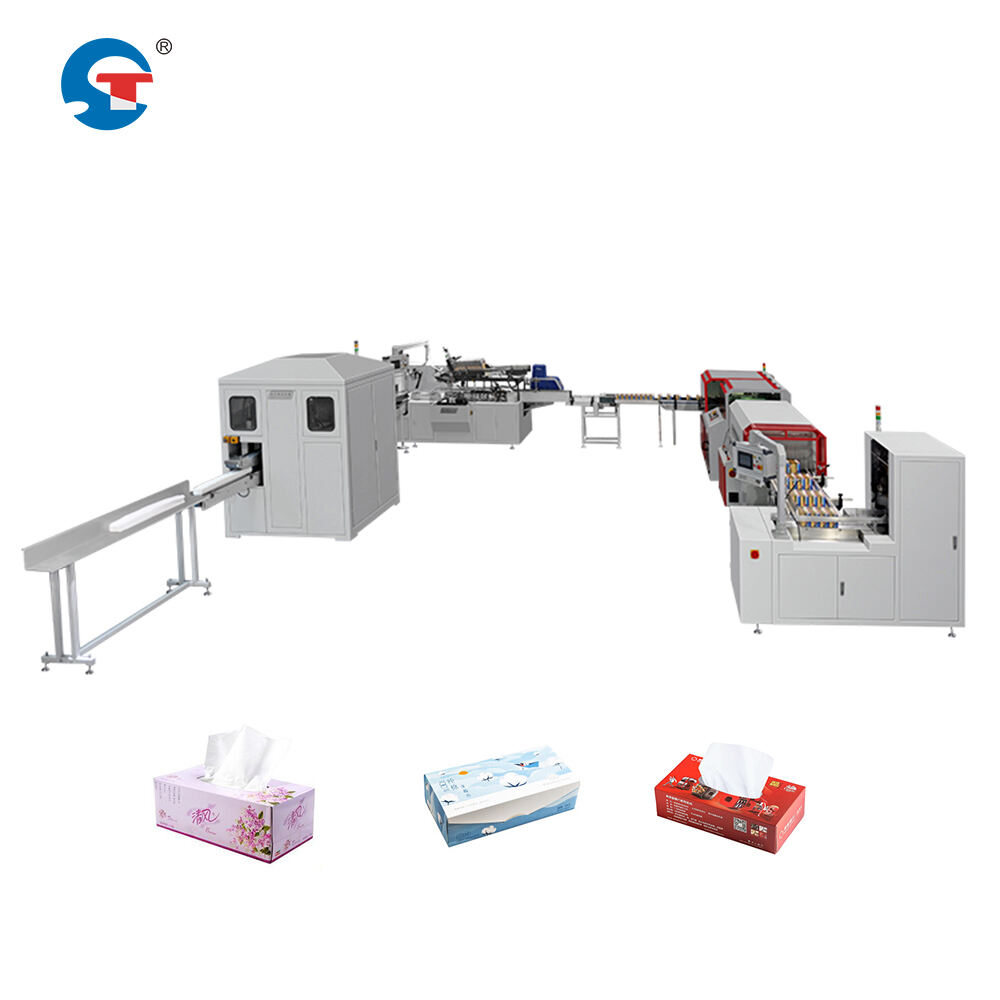

custom packaging machine

The custom packaging machine represents a cutting-edge solution in modern manufacturing, combining precision engineering with versatile functionality to meet diverse packaging needs. This sophisticated equipment utilizes advanced automation technology to handle various materials and product sizes, ensuring consistent and efficient packaging operations. The machine features a modular design that allows for easy customization according to specific production requirements, incorporating multiple packaging stations that can be configured for different processes such as filling, sealing, labeling, and coding. Its intelligent control system enables real-time monitoring and adjustment of packaging parameters, while the user-friendly interface simplifies operation and maintenance procedures. The machine's robust construction ensures durability and reliable performance in demanding industrial environments, while its precision components maintain high accuracy in package formation and sealing. It accommodates multiple packaging formats, from bags and boxes to bottles and containers, with quick changeover capabilities that minimize production downtime. The integration of quality control mechanisms, including vision systems and weight checkers, ensures that each package meets predetermined specifications. Advanced safety features protect operators while maintaining optimal production speeds, making it an essential tool for businesses seeking to optimize their packaging operations.