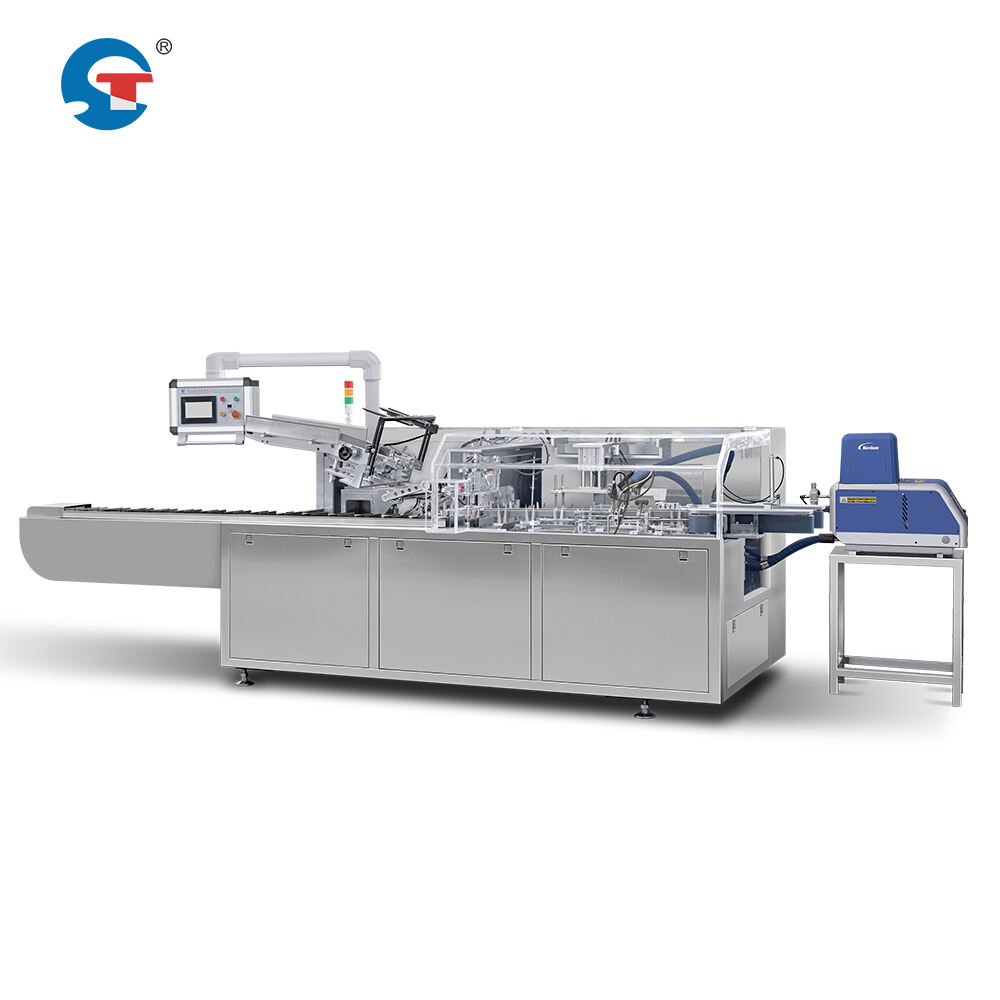

semi automatic packing machine

A semi automatic packing machine represents a versatile and efficient solution for businesses seeking to streamline their packaging operations. This innovative equipment combines manual intervention with automated processes to deliver optimal packaging results. The machine typically consists of a feeding system, a measuring unit, a sealing mechanism, and a control panel for operator interface. It can handle various product types, from granular materials to solid items, making it suitable for diverse industries including food processing, pharmaceuticals, and consumer goods. The technology incorporates precision sensors that ensure accurate product measurement and consistent packaging quality. Operating at speeds of up to 20-30 packages per minute, these machines maintain a balance between automation and human oversight. The system features adjustable parameters for different package sizes, material types, and sealing requirements. Modern semi automatic packing machines are equipped with digital controls, allowing operators to monitor and adjust settings easily. Safety features include emergency stop buttons, protective guards, and automatic fault detection systems. The machine's modular design facilitates easy maintenance and cleaning, while its compact footprint makes it suitable for facilities with limited space.