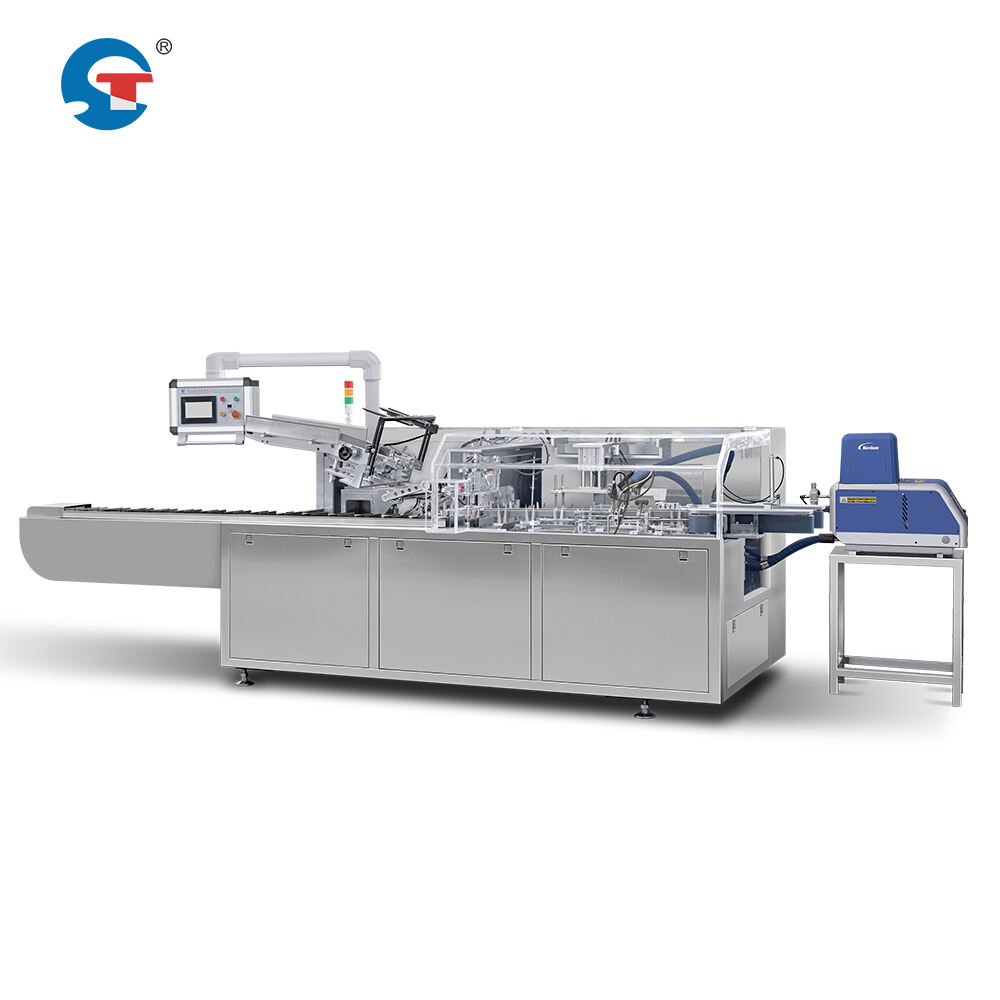

chocolate wrapping machine

The chocolate wrapping machine represents a pinnacle of confectionery automation technology, designed to efficiently package various chocolate products with precision and care. This sophisticated equipment handles multiple packaging styles, from individual piece wrapping to bulk packaging, accommodating different chocolate sizes and shapes. The machine incorporates advanced servo motor systems for precise control over wrapping operations, ensuring consistent packaging quality and maintaining the integrity of delicate chocolate products. Its modular design typically includes feeding systems, folding mechanisms, and sealing units that work in harmony to deliver professionally wrapped chocolates. The machine features adjustable speed settings, allowing production rates from 100 to 400 pieces per minute, depending on the model and product specifications. Temperature-controlled components prevent chocolate melting during the wrapping process, while smart sensors monitor product alignment and wrapping material tension. Modern chocolate wrapping machines also include user-friendly touch screen interfaces for easy operation and quick format changes, making them suitable for both large-scale manufacturers and artisanal chocolatiers. The equipment commonly handles various wrapping materials, including foil, paper, and composite films, providing versatility in packaging options to meet different market demands.