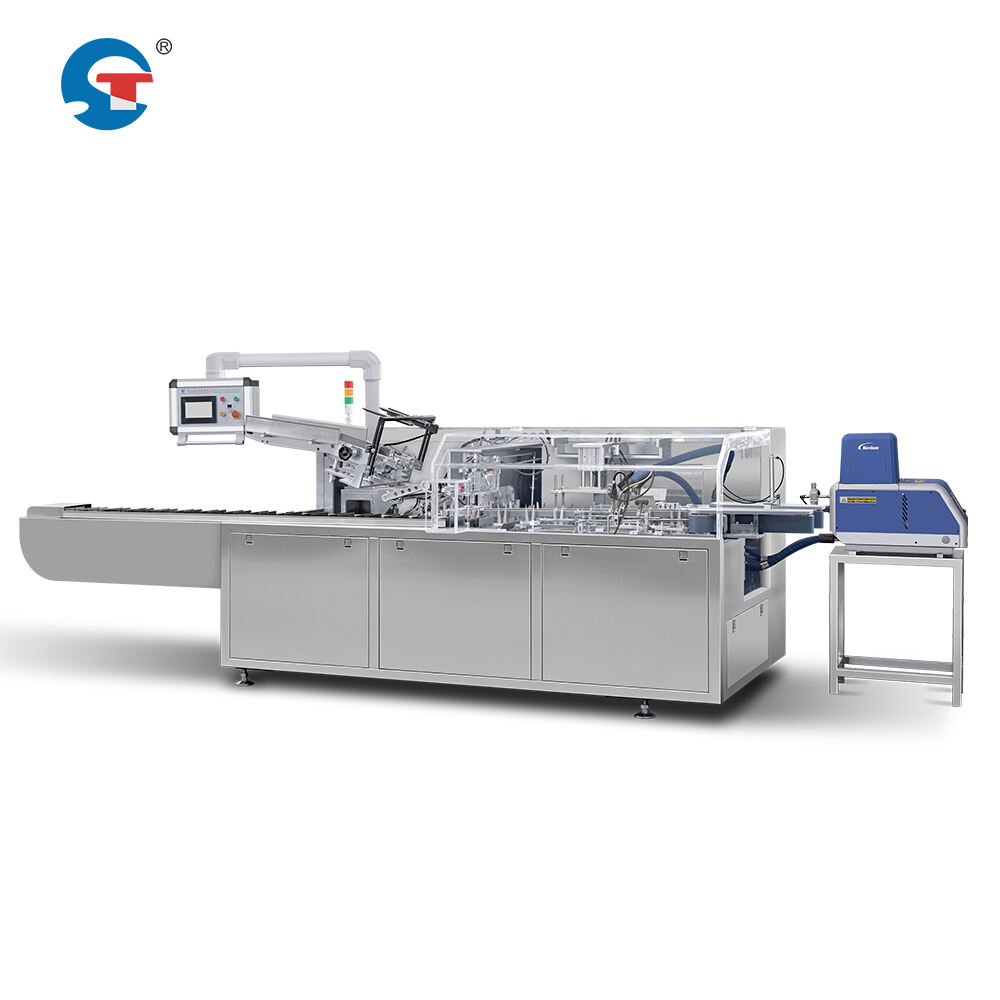

chocolate bar wrapping machine

The chocolate bar wrapping machine represents a pinnacle of automated confectionery packaging technology, designed to efficiently wrap individual chocolate bars with precision and speed. This sophisticated equipment combines mechanical and electronic systems to deliver consistent, high-quality packaging results. The machine features a continuous feed system that can handle various sizes of chocolate bars, utilizing servo-driven mechanisms to ensure accurate positioning and wrapping. Its advanced control system maintains optimal temperature conditions to prevent chocolate melting during the packaging process, while the automatic feeding mechanism carefully aligns each bar for perfect wrapper placement. The machine incorporates multiple wrapping stages, including primary film wrapping, folding, and sealing, all executed with remarkable precision. Modern models are equipped with touch-screen interfaces for easy operation and quick parameter adjustments, allowing operators to modify wrapping specifications for different product sizes. The system's modular design facilitates maintenance and cleaning, ensuring compliance with food safety standards. With production speeds capable of handling hundreds of bars per minute, these machines are essential for medium to large-scale chocolate manufacturers seeking to optimize their packaging operations while maintaining consistent quality.