Revolutionizing Packaging Efficiency with Advanced Cartoning Technology

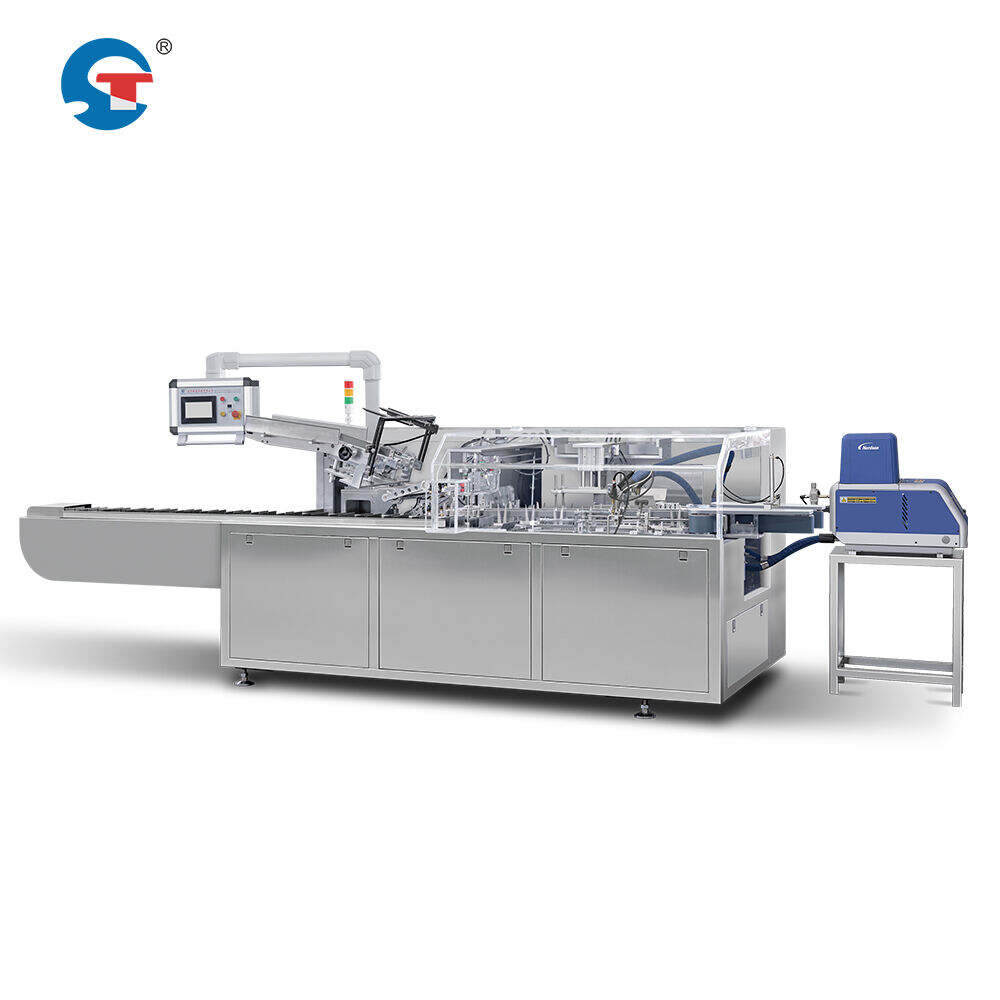

In today's competitive manufacturing landscape, the need for precise, efficient, and waste-reducing packaging solutions has never been more critical. Horizontal cartoning machines have emerged as a game-changing technology that transforms how businesses approach their packaging operations. These sophisticated systems not only streamline the packaging process but also significantly minimize errors and material waste, leading to substantial cost savings and improved production efficiency.

Modern manufacturing facilities are increasingly turning to horizontal cartoning machines to address the growing demands for faster production speeds while maintaining impeccable quality standards. These automated solutions represent a significant leap forward from traditional manual packaging methods, offering unprecedented accuracy and consistency in carton forming, product insertion, and sealing operations.

Core Components and Functionality of Modern Cartoning Systems

Advanced Mechanical Design Elements

Horizontal cartoning machines incorporate precision-engineered components that work in perfect synchronization. The carton magazine system ensures smooth and consistent blank feeding, while servo-driven mechanisms control the precise timing of product insertion. The integration of multiple conveyor systems and guide rails ensures proper product alignment and smooth transitions throughout the packaging process.

The mechanical architecture of these machines includes sophisticated folding mechanisms that carefully manipulate carton blanks into their final form. Each component is designed with tight tolerances to maintain consistent operation and minimize the risk of jams or misfeeds that could lead to waste.

Intelligent Control Systems and Monitoring

Modern horizontal cartoning machines feature advanced PLC systems and intuitive HMI interfaces that provide operators with real-time feedback and control. These smart systems continuously monitor various parameters including carton positioning, product presence, and seal integrity. The integration of vision systems and sensors enables immediate detection of potential issues before they result in waste or damaged products.

Machine learning algorithms can analyze operational data to predict maintenance needs and optimize performance parameters, further reducing the likelihood of errors and waste in the packaging process.

Error Prevention and Quality Assurance Features

Automated Inspection and Rejection Systems

Quality control in horizontal cartoning machines begins with comprehensive inspection systems that verify product presence, orientation, and condition before packaging. High-speed cameras and sensors examine each carton and product, ensuring proper assembly and identifying any defects. When irregularities are detected, sophisticated rejection mechanisms automatically remove faulty packages without disrupting the production flow.

These inspection systems can detect subtle issues such as improper seals, missing products, or damaged cartons with remarkable accuracy. The integration of multiple check points throughout the packaging process ensures that problems are caught early, minimizing material waste and preventing defective products from reaching the end of the line.

Real-time Error Detection and Correction

The latest horizontal cartoning machines employ advanced error detection algorithms that can identify and respond to issues in real-time. When variations in carton formation or product insertion are detected, the system can make immediate adjustments to prevent errors from occurring. This proactive approach significantly reduces waste by addressing potential problems before they result in rejected packages.

Additionally, these systems maintain detailed logs of all operations and errors, enabling manufacturers to analyze patterns and implement preventive measures for continuous improvement.

Waste Reduction Strategies and Sustainability Benefits

Material Optimization Technologies

Horizontal cartoning machines incorporate sophisticated material handling systems that minimize waste through precise control of packaging materials. Advanced feeding mechanisms ensure accurate carton blank separation and positioning, reducing the likelihood of material jams or damage. Servo-controlled movements optimize the use of packaging materials by maintaining consistent spacing and reducing over-packaging.

These machines also feature adjustable settings that can accommodate various carton sizes and materials, allowing manufacturers to fine-tune operations for maximum material efficiency. The ability to quickly adjust to different product specifications helps minimize setup waste and material loss during changeovers.

Environmental Impact and Sustainability

By reducing packaging errors and waste, horizontal cartoning machines contribute significantly to environmental sustainability efforts. The precision of these systems means less material ends up in landfills, while improved efficiency reduces energy consumption per unit packaged. Many modern machines are designed to work with eco-friendly packaging materials, supporting manufacturers' sustainability initiatives.

The reduction in waste also translates to lower disposal costs and a smaller carbon footprint for manufacturing operations. These environmental benefits align with increasing consumer demand for sustainable packaging solutions and help companies meet their corporate social responsibility goals.

Future Innovations and Industry Trends

Digital Integration and Industry 4.0

The future of horizontal cartoning machines lies in their integration with Industry 4.0 technologies. Advanced connectivity features enable these machines to communicate with other production equipment, sharing data and coordinating operations for optimal efficiency. The implementation of digital twins allows for virtual testing and optimization of packaging processes before physical implementation.

Emerging technologies such as augmented reality are being incorporated into maintenance and operation procedures, helping technicians quickly identify and resolve issues that could lead to waste or errors.

Adaptive Technology and Flexible Solutions

Next-generation horizontal cartoning machines are being developed with increasingly adaptive capabilities. These systems can automatically adjust to varying product sizes and shapes, reducing the need for manual intervention and minimizing setup waste. Machine learning algorithms continue to improve their ability to predict and prevent potential issues, further reducing error rates and material waste.

The integration of robotics and flexible automation solutions allows these machines to handle an ever-wider range of packaging requirements while maintaining high efficiency and minimal waste.

Frequently Asked Questions

What are the key maintenance requirements for horizontal cartoning machines?

Regular maintenance of horizontal cartoning machines includes cleaning and lubricating moving parts, checking and calibrating sensors, inspecting wear components, and updating control system software. Following a preventive maintenance schedule is crucial for maintaining optimal performance and minimizing waste due to mechanical issues.

How do horizontal cartoning machines handle different carton sizes?

Modern horizontal cartoning machines feature quick-change tooling and automated adjustment systems that allow for rapid changeover between different carton sizes. Digital controls enable operators to store and recall settings for various products, ensuring consistent performance across different packaging formats.

What ROI can companies expect from implementing horizontal cartoning machines?

Companies typically see return on investment through reduced labor costs, increased production speeds, and significant reductions in material waste. The exact ROI depends on factors such as production volume, current error rates, and labor costs, but many organizations report payback periods of 12-24 months through improved efficiency and waste reduction.

Table of Contents

- Revolutionizing Packaging Efficiency with Advanced Cartoning Technology

- Core Components and Functionality of Modern Cartoning Systems

- Error Prevention and Quality Assurance Features

- Waste Reduction Strategies and Sustainability Benefits

- Future Innovations and Industry Trends

- Frequently Asked Questions