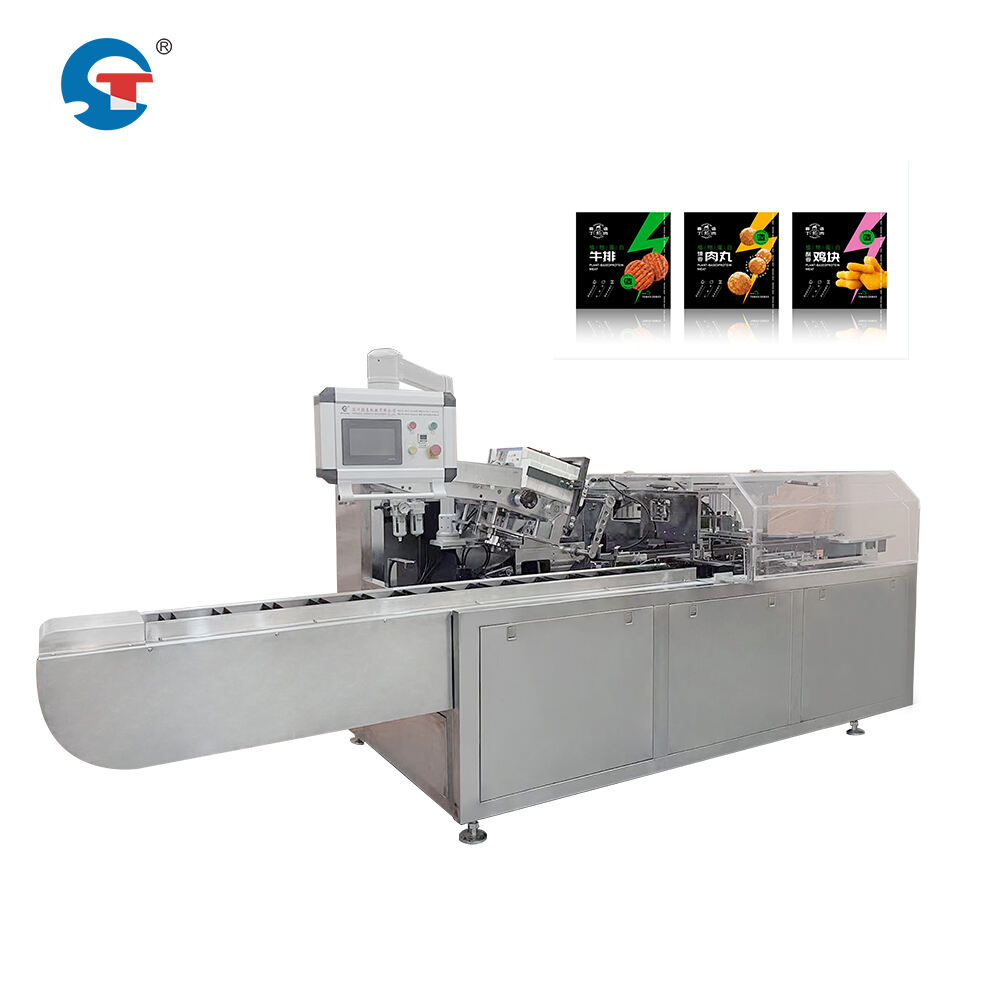

sweet box packing machine

The sweet box packing machine represents a cutting-edge solution in automated packaging technology, designed specifically for the confectionery industry. This sophisticated equipment seamlessly handles the entire packaging process, from box formation to final sealing. Operating at speeds of up to 40 boxes per minute, the machine incorporates advanced servo motor systems for precise control and consistent performance. The machine's versatile design accommodates various box sizes, ranging from small gift boxes to larger assortment packages, with quick changeover capabilities. Its intelligent control system features a user-friendly touch screen interface, allowing operators to easily adjust parameters and monitor production metrics in real-time. The machine's construction utilizes food-grade stainless steel, ensuring compliance with hygiene standards while providing durability in continuous operation. Key functions include automatic box feeding, product counting and placement, quality inspection through integrated vision systems, and secure sealing mechanisms. The machine's modular design facilitates easy maintenance and cleaning, while its compact footprint optimizes floor space utilization in production facilities.