semi automatic cartoner

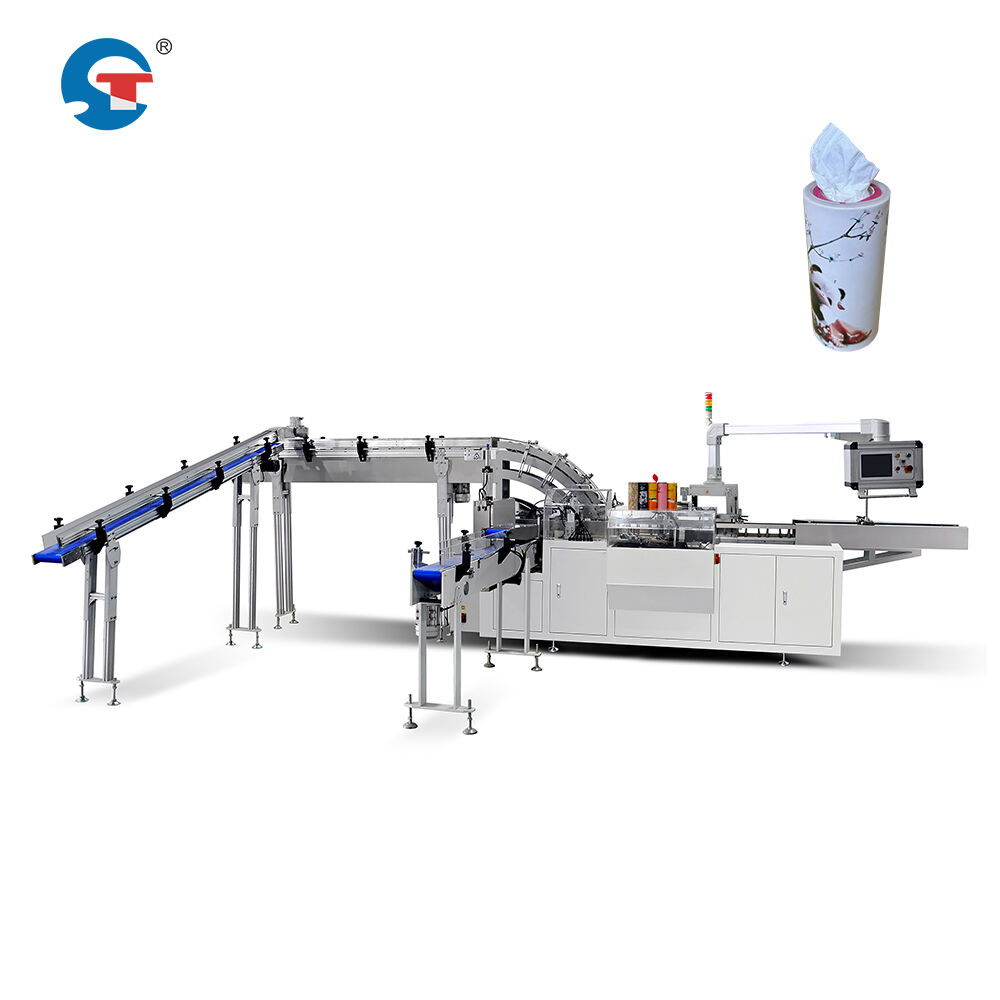

A semi automatic cartoner represents a crucial piece of packaging machinery that combines manual operation with automated functionality to efficiently pack products into cartons or boxes. This versatile equipment streamlines the packaging process by automating critical steps while maintaining operator control for quality assurance. The machine typically features a carton magazine for storing flat cartons, an erecting mechanism that forms the cartons, and a conveyor system that moves products through the packaging sequence. The operator's role involves feeding products and monitoring the process, while the machine handles complex tasks like carton forming, product insertion, and closure. Modern semi automatic cartoners incorporate advanced features such as adjustable speed controls, precise timing mechanisms, and various safety interlocks to ensure reliable operation. These machines can handle diverse product sizes and carton styles, making them suitable for industries ranging from food and beverage to pharmaceuticals and consumer goods. The equipment's modular design allows for customization based on specific packaging requirements, while maintaining consistent output quality and reducing labor costs compared to fully manual operations.