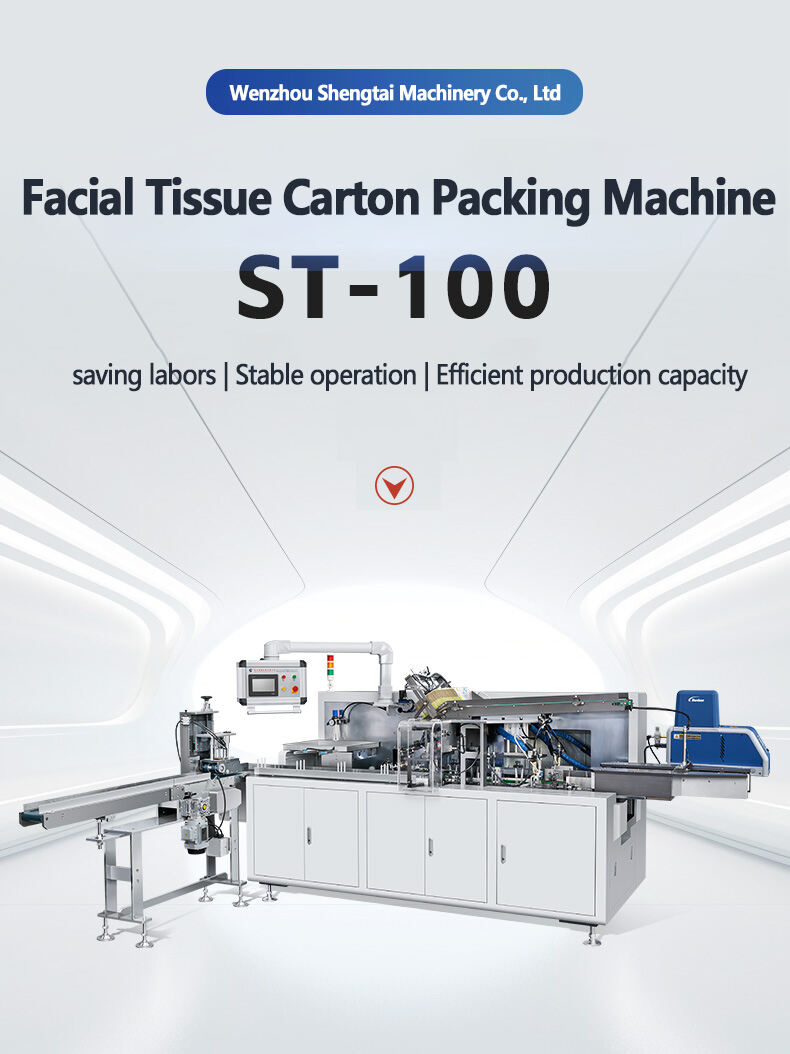

automatic carton box packing machine

The automatic carton box packing machine represents a pinnacle of modern packaging automation technology, designed to streamline and optimize the packaging process in various industries. This sophisticated equipment combines mechanical precision with intelligent control systems to automatically fold, fill, and seal carton boxes with remarkable efficiency. The machine features advanced servo motors that ensure precise movements and consistent operation, while its intuitive touch screen interface allows for easy parameter adjustments and operation monitoring. Its modular design incorporates multiple stations including box erecting, product loading, and sealing mechanisms, all working in seamless coordination. The machine can handle various box sizes and styles, with quick changeover capabilities to accommodate different product requirements. Built with industrial-grade materials and components, it maintains reliable performance even during extended operation periods. The system includes safety features such as emergency stops and protective guards, ensuring operator safety while maintaining high productivity levels. With processing speeds capable of handling up to several dozen boxes per minute, it significantly reduces labor costs while improving packaging consistency and quality.