Pharmaceutical manufacturing demands precision, efficiency, and compliance with stringent quality standards. As the industry continues to evolve with increasing production volumes and regulatory requirements, manufacturers are constantly seeking innovative solutions to streamline their packaging operations. Among the most transformative investments in modern pharmaceutical packaging is the pill plate cartoning machine, a specialized piece of equipment designed to automate the cartoning process for pharmaceutical products packaged in blister plates. This sophisticated machinery represents a significant leap forward in packaging automation, offering manufacturers the ability to maintain consistent quality while dramatically increasing throughput and reducing operational costs.

Understanding the Critical Role of Automated Cartoning in Pharmaceutical Manufacturing

The Evolution of Pharmaceutical Packaging Technology

The pharmaceutical packaging landscape has undergone a remarkable transformation over the past decade, driven by advances in automation technology and increasing regulatory pressures. Traditional manual cartoning processes, once considered adequate for smaller production runs, have become bottlenecks in modern pharmaceutical manufacturing facilities. The shift toward automated cartoning solutions represents more than just a technological upgrade; it signifies a fundamental change in how pharmaceutical companies approach packaging efficiency, quality control, and regulatory compliance.

Modern pharmaceutical manufacturers face unprecedented challenges in meeting growing global demand while maintaining the highest quality standards. Consumer expectations for product safety, coupled with increasingly complex regulatory frameworks across different markets, have created an environment where automated packaging solutions are no longer luxury additions but essential components of competitive manufacturing operations. The integration of advanced cartoning machinery has become a strategic imperative for companies seeking to maintain market position while optimizing operational efficiency.

Defining the Scope and Functionality of Modern Cartoning Systems

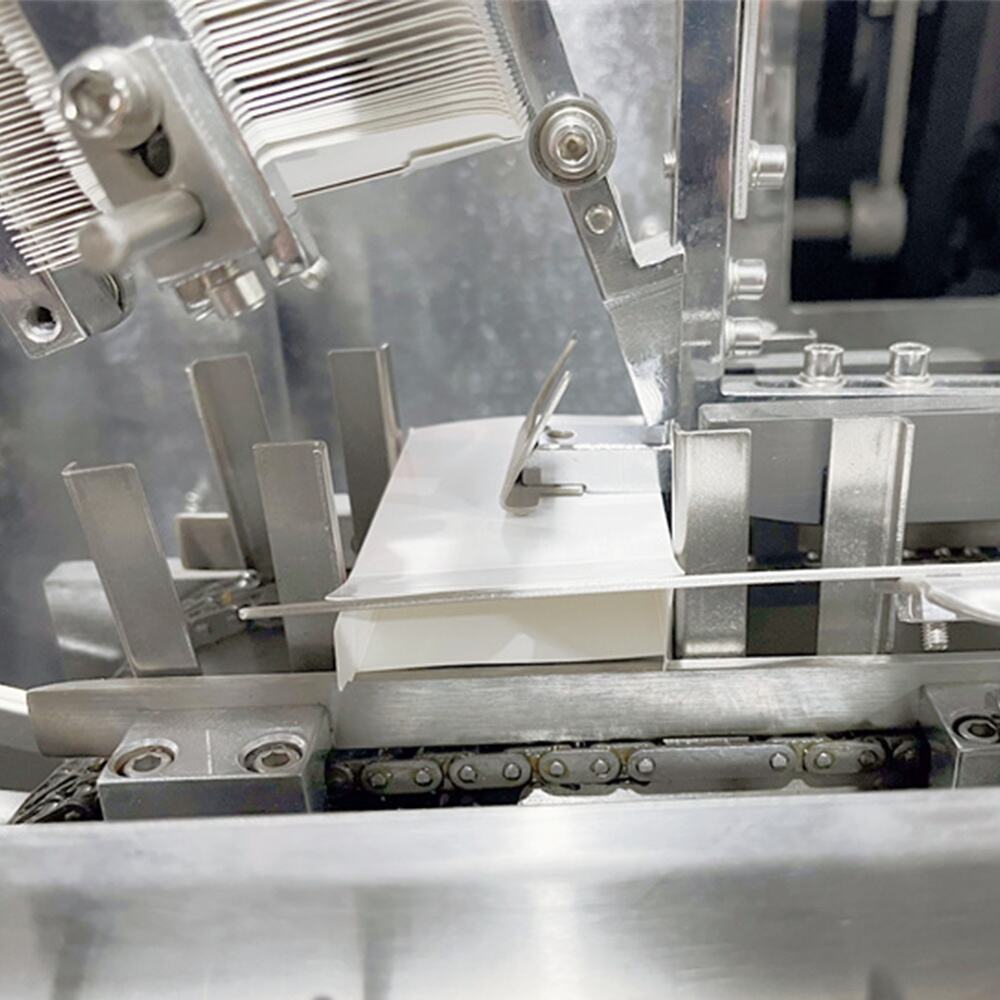

A comprehensive understanding of cartoning machine functionality reveals the sophisticated engineering behind these systems. Modern cartoning equipment integrates multiple processes into a single, streamlined operation, including carton feeding, product insertion, leaflet insertion, quality inspection, and carton sealing. These machines are designed to handle various pharmaceutical packaging formats, from individual blister packs to complex multi-product configurations, ensuring versatility across different product lines and manufacturing requirements.

The technological sophistication of contemporary cartoning systems extends beyond basic automation to include advanced features such as vision inspection systems, serialization capabilities, and real-time quality monitoring. These integrated technologies enable manufacturers to achieve levels of precision and consistency that would be impossible with manual processes, while simultaneously reducing the risk of human error and contamination. The result is a packaging solution that not only meets current regulatory requirements but also provides the flexibility to adapt to future industry changes and emerging compliance standards.

Operational Efficiency Gains Through Advanced Cartoning Automation

Throughput Enhancement and Production Speed Optimization

The implementation of automated cartoning machinery delivers immediate and measurable improvements in production throughput, with many facilities experiencing speed increases of 300% to 500% compared to manual operations. These productivity gains stem from the machine's ability to maintain consistent operating speeds without the variability inherent in human-operated processes. Modern pill plate cartoning machines can process hundreds of units per minute while maintaining precise positioning and quality standards, enabling manufacturers to meet ambitious production targets without compromising on quality or safety requirements.

Beyond raw speed improvements, automated cartoning systems provide enhanced predictability in production scheduling and capacity planning. The consistent operating parameters of these machines allow production managers to calculate precise completion times for manufacturing runs, enabling more accurate delivery commitments to customers and more efficient utilization of facility resources. This predictability extends to maintenance scheduling, as automated systems provide detailed operational data that enables proactive maintenance planning and minimizes unexpected downtime events that can disrupt production schedules.

Labor Cost Reduction and Workforce Optimization Strategies

The economic impact of automated cartoning extends significantly beyond initial productivity gains to encompass comprehensive labor cost optimization. While the upfront investment in cartoning machinery represents a substantial capital expenditure, the long-term labor savings often justify the investment within 18 to 24 months of implementation. Automated systems typically require fewer operators per shift while enabling existing workforce members to focus on higher-value activities such as quality assurance, process monitoring, and equipment optimization rather than repetitive manual tasks.

The strategic reallocation of human resources enabled by automation creates opportunities for skill development and career advancement within the organization. Employees previously engaged in manual cartoning operations can be trained to operate and maintain sophisticated automated equipment, developing valuable technical skills that contribute to their professional growth while enhancing the organization's overall technical capabilities. This transformation of workforce responsibilities often results in improved job satisfaction and reduced employee turnover, further contributing to the economic benefits of automation investment.

Quality Control and Compliance Advantages in Automated Packaging

Precision and Consistency in Product Packaging

The precision capabilities of modern cartoning machinery establish new benchmarks for packaging quality and consistency in pharmaceutical manufacturing. These systems utilize advanced servo-driven mechanisms and computerized control systems to ensure that every carton is formed, filled, and sealed to exact specifications, eliminating the variations that inevitably occur in manual processes. The mechanical precision of automated systems ensures consistent carton dimensions, proper product positioning, and uniform seal integrity across all production units, contributing to enhanced product protection and improved shelf presentation.

Quality consistency extends beyond physical packaging parameters to encompass critical aspects such as leaflet insertion accuracy, product orientation verification, and carton closure integrity. Modern pill plate cartoning machine systems incorporate sophisticated vision inspection technologies that verify proper leaflet placement, detect missing or damaged products, and ensure correct carton assembly before the final sealing process. This comprehensive quality verification approach significantly reduces the risk of packaging errors reaching consumers while minimizing the need for costly post-production quality inspections and potential product recalls.

Regulatory Compliance and Documentation Requirements

Pharmaceutical manufacturing operates within one of the most heavily regulated industrial environments, where packaging compliance directly impacts product approval, market access, and ongoing operational authorization. Automated cartoning systems provide integrated compliance capabilities that support adherence to FDA, EMA, and other international regulatory standards through comprehensive documentation, traceability features, and validation protocols. These systems generate detailed operational logs that provide complete audit trails for every packaged unit, including timing data, quality checkpoints, and any detected anomalies during the packaging process.

The validation advantages of automated cartoning equipment extend to support for emerging regulatory requirements such as serialization and track-and-trace mandates. Modern systems can integrate seamlessly with serialization equipment to ensure that every packaged unit receives appropriate identification codes and documentation, supporting global supply chain transparency initiatives. This integrated approach to compliance reduces the complexity of meeting multiple regulatory requirements across different markets while providing the flexibility to adapt to evolving regulatory landscapes without requiring major equipment modifications or operational disruptions.

Economic Analysis and Return on Investment Considerations

Capital Investment Assessment and Financial Planning

The financial evaluation of cartoning machine investments requires a comprehensive analysis that extends beyond initial purchase costs to encompass installation, training, validation, and ongoing operational expenses. While high-quality cartoning systems represent significant capital investments, typically ranging from several hundred thousand to over one million dollars depending on capabilities and throughput requirements, the economic benefits often justify these expenditures through multiple value streams. Manufacturing organizations must consider factors such as labor cost savings, productivity improvements, quality enhancement benefits, and reduced waste when calculating the total economic impact of automation investments.

The financial planning process for cartoning automation should incorporate detailed projections of production volume growth, market expansion opportunities, and potential cost savings from improved efficiency. Many pharmaceutical manufacturers discover that automated cartoning capabilities enable them to pursue new market opportunities or expand existing product lines that would not be economically viable with manual packaging processes. These revenue enhancement opportunities, combined with direct cost savings, often result in return on investment periods significantly shorter than the equipment's expected operational lifespan, making automation investments highly attractive from a strategic financial perspective.

Long-term Cost Savings and Operational Benefits

The long-term economic advantages of automated cartoning extend far beyond immediate labor savings to encompass comprehensive operational improvements that compound over time. Reduced material waste, improved energy efficiency, lower maintenance costs compared to multiple manual workstations, and decreased facility space requirements all contribute to ongoing cost reductions that continue throughout the equipment's operational life. Additionally, the enhanced production capacity provided by automated systems often eliminates the need for facility expansion or additional production lines that would otherwise be required to meet growing demand.

The strategic value of cartoning automation becomes particularly evident when considering market responsiveness and competitive positioning. Automated systems enable rapid production scaling in response to market demands, seasonal variations, or emergency requirements without the delays associated with workforce expansion and training. This operational flexibility provides significant competitive advantages in dynamic pharmaceutical markets where the ability to quickly respond to opportunities or supply chain disruptions can determine market success and long-term profitability.

Integration Challenges and Implementation Best Practices

Technical Integration with Existing Manufacturing Systems

Successful integration of cartoning automation requires careful consideration of existing manufacturing infrastructure, production flow patterns, and quality control systems to ensure seamless operation within established processes. The technical complexity of modern pharmaceutical manufacturing facilities demands that new cartoning equipment interfaces effectively with upstream and downstream processes, including blister packaging lines, labeling systems, case packing equipment, and inventory management systems. Proper integration planning must address mechanical interfaces, electrical connections, communication protocols, and data exchange requirements to create a cohesive and efficient production environment.

The integration process extends beyond physical and technical considerations to encompass workflow optimization and process synchronization across the entire packaging line. Successful implementations require detailed analysis of production bottlenecks, material flow patterns, and quality control checkpoints to ensure that the new cartoning system enhances overall line efficiency rather than creating new constraints. This comprehensive approach to integration often reveals opportunities for additional process improvements and optimization that further enhance the value of the automation investment.

Staff Training and Change Management Strategies

The human element of cartoning automation implementation requires careful attention to training programs, change management processes, and ongoing skill development initiatives to ensure successful adoption and optimal performance. Effective training programs must address not only technical operation procedures but also troubleshooting techniques, preventive maintenance protocols, and quality assurance responsibilities. The complexity of modern cartoning systems demands that operators develop sophisticated technical skills while maintaining focus on pharmaceutical quality standards and regulatory compliance requirements.

Change management strategies must acknowledge the significant transition from manual to automated processes while addressing potential concerns about job security, role changes, and skill requirements. Successful implementations typically involve extensive stakeholder engagement, clear communication about the benefits and expectations of automation, and comprehensive support systems to help employees adapt to new responsibilities and working environments. Organizations that invest in thorough change management processes often experience smoother implementation timelines, higher employee satisfaction, and more effective utilization of their automation investments.

FAQ

What factors should be considered when selecting a pill plate cartoning machine for pharmaceutical manufacturing?

Selecting the appropriate cartoning machine requires evaluation of multiple technical and operational factors including production volume requirements, product size and configuration specifications, integration capabilities with existing equipment, regulatory compliance features, and long-term scalability needs. Manufacturers should assess throughput capabilities, changeover flexibility, quality inspection systems, and validation support to ensure the selected equipment meets both current and anticipated future requirements. Additionally, consideration of supplier support capabilities, spare parts availability, and training resources is essential for successful long-term operation.

How long does it typically take to see return on investment from cartoning automation?

Return on investment timelines for cartoning automation typically range from 18 to 36 months, depending on factors such as production volume, labor costs, efficiency gains, and quality improvements achieved through automation. Higher-volume operations often experience shorter payback periods due to greater labor cost savings and productivity improvements, while facilities with complex packaging requirements may realize additional benefits through reduced errors and improved compliance capabilities. The calculation should include direct cost savings, productivity improvements, quality enhancements, and potential revenue opportunities enabled by increased capacity and capability.

What maintenance requirements are associated with automated cartoning systems?

Automated cartoning systems require regular preventive maintenance including lubrication, component inspection, calibration verification, and software updates to maintain optimal performance and regulatory compliance. Typical maintenance schedules include daily cleaning and inspection procedures, weekly lubrication and adjustment tasks, monthly component replacement schedules, and annual comprehensive system validation processes. Modern systems often include predictive maintenance capabilities that monitor component condition and performance parameters to optimize maintenance timing and minimize unexpected downtime events.

Can cartoning machines accommodate different product sizes and packaging configurations?

Contemporary cartoning machines offer extensive flexibility for handling various product sizes, carton configurations, and packaging formats through adjustable components, quick-change tooling systems, and programmable control parameters. Many systems can accommodate different blister pack sizes, multiple products per carton, various leaflet configurations, and different carton styles with minimal changeover time and effort. This flexibility enables manufacturers to efficiently process multiple product lines on the same equipment while maintaining high efficiency and quality standards across all packaging configurations.

Table of Contents

- Understanding the Critical Role of Automated Cartoning in Pharmaceutical Manufacturing

- Operational Efficiency Gains Through Advanced Cartoning Automation

- Quality Control and Compliance Advantages in Automated Packaging

- Economic Analysis and Return on Investment Considerations

- Integration Challenges and Implementation Best Practices

-

FAQ

- What factors should be considered when selecting a pill plate cartoning machine for pharmaceutical manufacturing?

- How long does it typically take to see return on investment from cartoning automation?

- What maintenance requirements are associated with automated cartoning systems?

- Can cartoning machines accommodate different product sizes and packaging configurations?